Using the Tool Posts tab, you can manually synchronize operations. For cutting OD turning features, FeatureCAM can automatically synchronize operations and load the appropriate tools in each tool post. All of the automatic synchronized turning requires a lathe with two opposing tool posts.

Pinch turning

Pinch turning is also referred to as balanced turning. It can be used for either roughing or finishing. With pinch turning, both tools cut the same curve (although one is above the axis of rotation and the other is below). The feed rate that is calculated for each tool is doubled. The first tool actually leaves a spiral of material after its finish pass and the second tool is positioned at min Z so that it cuts the spiral of material left by the first tool. The tools cut at the same time so that the time needed for the finish pass is halved. The tool that is selected for the operation is automatically inserted into both tool posts.

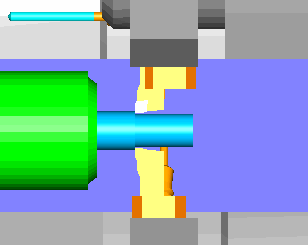

The following image shows an example of pinch turning.

To set this strategy on a turning operation:

- Bring up the Strategy tab of the turn operation

- Make sure that the roughing or finishing pass is enabled by selecting the Rough or Finish option.

- Select Pinch turning from the menu after the option.

Follow turning

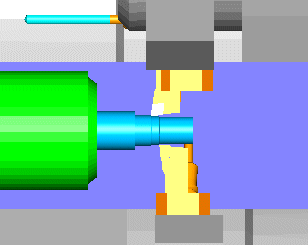

Follow turning is typically performed when roughing. Each tool post removes a standard depth of cut. The second tool post removes a depth of cut below the cut left by the first tool post. The tool posts wait or synchronize at the start of the cut. One tool post is a fixed distance in front of tool post 2. The image below illustrates follow turning. The top tool is in front of the bottom tool and the bottom tool is cutting deeper in X.

To set this strategy on a turning operation:

- Bring up the Strategy tab of the turn operation

- Make sure that the roughing or finishing pass is enabled by selecting the Rough or Finish option.

- Select Follow turning from the menu after the option.

- Enter the Follow distance on the Strategy tab of the operation.