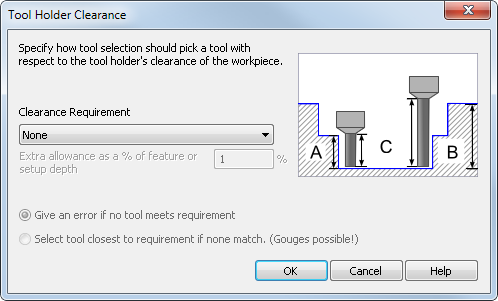

Use the Tool Holder Clearance dialog to specify an additional clearance for FeatureCAM's automatic tool selection to prevent tool holder gouges.

To display the Tool Holder Clearance dialog, click Tool Holder Clearance on the Tool Selection page of the Machining Attributes dialog.

To specify a tool selection clearance:

- In the

Clearance Requirement list, select the clearance you want between the tool holder and the part. Select from:

- None — Select this option to leave no additional clearance. Old part files select the same tools as before.

- Feature — Select this option to ensure the tool is long enough for the tool holder to clear the feature.

- Setup — Select this option to ensure the tool is long enough for the tool holder to clear the total depth below the setup.

- Stock — Select this option to ensure the tool is long enough for the tool holder to clear the total depth into the stock.

- Enter an Extra allowance as a % of feature or setup depth to leave extra clearance of the tool holder above the feature, setup, or stock

- Select how tool selection is affected if no matching tool is found:

-

Give an error if no tool meets requirements —

FeatureCAM does not select a tool for the operation, so an error is shown during NC code generation. In the

Operation List, a red exclamation point

is displayed beside operations with no tool selected.

is displayed beside operations with no tool selected.

- Select tool closest to requirements if none match — this enables you to generate NC code, but it may result in tool holder gouges because a smaller tool may be used.

-

Give an error if no tool meets requirements —

FeatureCAM does not select a tool for the operation, so an error is shown during NC code generation. In the

Operation List, a red exclamation point

- Click OK to close the dialog.