Constant DOC — See Rough depth of cut.

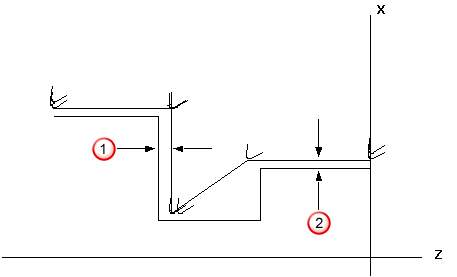

X finish allowance

Z finish allowance

X finish allowance

Z finish allowance — See X finish allowance.

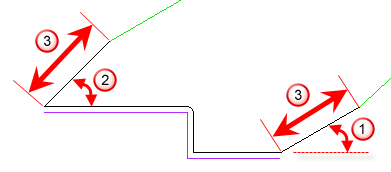

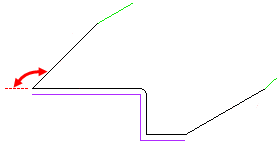

Rough Engage angle — Enter the angle at which the tool enters the stock in roughing operations when TNR comp is off.

Finish Engage angle — Enter the angle at which the tool enters the stock in finish operations when TNR comp is off.

Rough withdraw angle — Enter the angle at which the tool withdraws from the stock after cutting during roughing operations when TNR comp is off.

Finish withdraw angle — Enter the angle at which the tool withdraws from the stock after cutting during finish operations when TNR comp is off.

Withdraw length — This is the distance along the withdraw angle line in which the tool withdraws before returning for the next step.

Withdraw length

Withdraw length

Boundary

Boundary

Clearance

Clearance

Depth

Depth

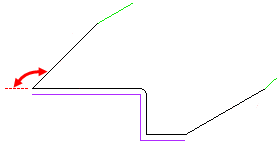

Use Clearance as finish withdraw length — When selected, the Clearance value is used as the approach and withdraw length for finishing moves. When deselected, the Withdraw length value is used.

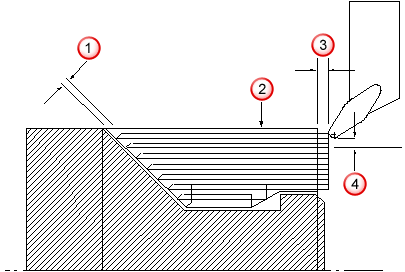

Tool nose radius compensation

Enable this option to ignore the tool radius when generating passes for Turn, Bore, and Face features. The actual part geometry is output as the toolpath. It is assumed that the tool radius compensation will be performed by the operator at the machine tool when this option is enabled.

Select whether you want TNR comp for Rough, Semi-Finish, and Finish operations. Enter the Lead-in angle, Lead-out angle, and Lead distance parameters for TNR comp.

|

Turn feature example

|

|

Rough lead in angle — Enter the angle at which the tool enters the stock in roughing operations when TNR comp is on.

Finish lead in angle — Enter the angle at which the tool enters the stock in finish operations when TNR comp is on.

Rough lead out angle — Enter the angle at which the tool withdraws from the stock after cutting during roughing operations when TNR comp is on.

Finish lead out angle — Enter the angle at which the tool withdraws from the stock after cutting during finish operations when TNR comp is on.

Reuse path in canned cycle — Relates to Use canned cycle. Enable this option to output the curve to the NC file once and then reference it in both the Rough and Finish canned cycles. This option is enabled by default.

Canned cycle clearance X and Z — These attributes control the tool location before the start of a turning canned cycle. The tool location is obtained by applying the X and Z clearances to the start point of the curve.

Back cutting engage arc radius — Specify the size of the arc at the beginning of each cut in a Back Cutting strategy. Enter a radius or select use DOC to use the DOC value.

Back cutting withdraw dist. — Enter the distance the tool withdraws at the end of each cut before returning for the next step.