Turn/milling in FeatureCAM allows the combination of turning and milling features on lathes with powered rotary tools, and supports the normal Z and X axes of turning combined with the C and optional Y-axis.

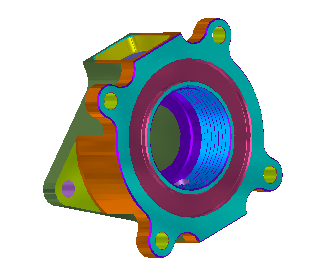

The yoke shown in the first image, could be manufactured with a C axis lathe in two setups or using a C axis lathe with a subspindle. The second image is a piece that requires a Y-axis due to the flat pockets on the top and bottom of the piece. (If these pockets were wrapped, they would have a curved bottom and then they could be manufactured without a Y-axis).

When creating features, you are given the choice of creating turning features or turn/mill features. Turn/mill features assume powered tools, and turning features assume that the tool does not spin. For example, you can make a hole along the Z-axis with both feature types, but the milled one uses rotary tools, and the turned hole uses a drill that does not spin.

Turning and turnmill features can be mixed in a single setup. Turning features are identical to those on a 2-axis lathe and milling features are created the same as for a 3-axis mill, except that you are given new choices for positioning and orienting the features either on the OD or on the face of the part.

Tool selection in turn/milling is similar to milling and turning, except that rotary tools are automatically classified as either parallel to the X-axis or Z-axis.

All forms of simulation (Centerline, 2D and 3D solid) are supported. In 3D simulation the rotation of the part is accurately simulated.