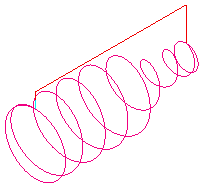

Select a cutting style from:

-

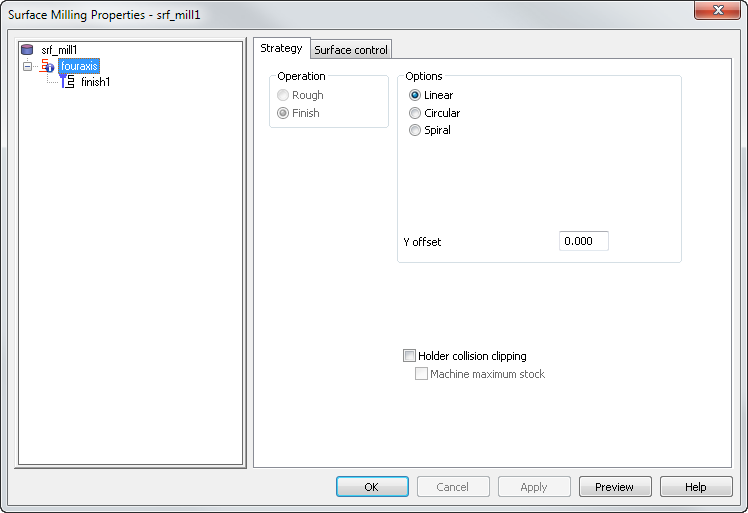

Linear

Linear rotary milling causes the tool to traverse along the index axis in straight lines, with the rotary axis only used at the end of each pass to reposition the job.

-

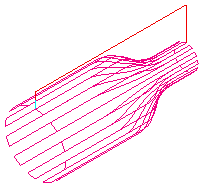

Circular

In circular milling the job rotates with the tool at a fixed position, effectively machining a circle. The tool then steps over the required amount and machines the next circle.

-

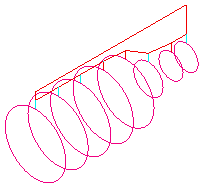

Spiral

A continuous spiral is cut along the length of the job when spiral milling is used. To ensure a clean finish a full circle is cut at the two ends. Because rotation is continuous, only Climb and Conventional milling are available (so, you must have a rotary head that can make an unlimited number of rotations).

Y offset — Enter a distance to avoid cutting on the center of the tool.

Holder collision clipping — Clips the toolpath where the holder or shank collides with a part surface, check surface, or unmachined stock. When selected, the Holder clearance and Shank clearance attributes are displayed on the Milling tab for the operation.

Machine maximum stock — Use with Holder collision clipping to machine the stock as close to the part without causing a holder collision. This creates smoother toolpaths with fewer retracts, which can improve the surface finish and reduce the machining time, but may cause increased air cutting on some parts.