You can use the Drill/Mill Options dialog to edit the feature-level drilling and milling options.

To display the Drill/Mill Options dialog, select Drill/Mill on the Strategy tab of the Hole Feature Properties dialog, then click Drill/Mill Options.

Select the strategies that you want to enable. The options are:

- Drill full diameter

- Rough with Drill, Finish with Bore

- Rough with Drill, Finish with Ream

- Rough with Endmill, Finish with Bore

- Rough with Endmill, Finish with Ream

-

Rough with Endmill, Finish with Endmill

- Finish Bottom

- Helical Side Finish — Select this option to use a continuous spiral for the Finish pass. Enter a Pitch to control the tightness of the spiral.

-

Rough with Endmill to full diameter — this option lets

FeatureCAM rough to the final hole diameter without having a finish pass.

- Use hole milling canned cycle if available ( ) — For machines that support hole/bore milling, such as Heidenhain Cycle 208, Siemens POCKET4, Fagor G88, and Haas G12/13. The hole milling canned cycle is posted using the hole milling format in XBUILD. If you enter a G code, for example G208, for the Hole Milling cycle in the NC Codes dialog in XBUILD, that code displays in the brackets after this attribute name, for example Use hole milling canned cycle if available (G208).

If you select more than one strategy, FeatureCAM works down the strategy list in the dialog until it finds a strategy that can complete the hole.

Spot Drill — Select this option to add a spot drill operation to the Hole feature.

Attempt chamfer w/ spot — Select this option to try to cut the chamfer during spot drilling. If no available tool can spot and chamfer without gouging the hole, a separate chamfer operation is created.

Ream before chamfer — Select this option to do the Ream operation before the Chamfer operation. This avoids pushing any kind of burr or edge back up onto the chamfer if the chamfer is a sealing surface.

Cutter comp — Select cutter compensation for milled holes.

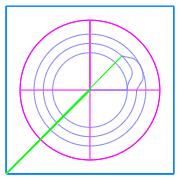

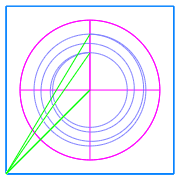

Use continuous spiral — Select this option to use an NT Continuous Spiral toolpath, which eliminates nearly all stepovers.

|

Use continuous spiral deselected

|

Use continuous spiral selected

|

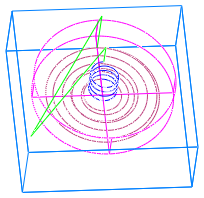

You can use Helical ramping with Use continuous spiral, for example:

Traditional spiral toolpaths can produce spikes in tool load. Another advantage of NT continuous spiral is that the tool load increases gradually.