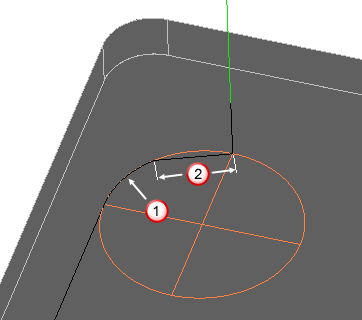

The lead in moves for finish passes for closed milled features such as pockets and bosses consist of a short linear move and an arc ramp on move. These moves are included to accommodate the cutter compensation requirements of many controllers.

The radius of the arc  is controlled by the Ramp diameter % in the Stepover/Lead tab, which is specified as a percentage of the tool diameter.

is controlled by the Ramp diameter % in the Stepover/Lead tab, which is specified as a percentage of the tool diameter.

The default length of the linear move  is the Finish allowance of the roughing pass of the feature.

is the Finish allowance of the roughing pass of the feature.

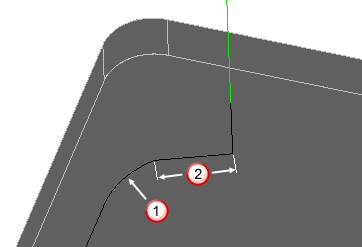

You can change the length of the linear move by setting the Minimum ramp distance milling attribute on the finish pass to an explicit distance, or by setting the Minimum ramp distance % default attribute as a percentage of the tool diameter.

If you set a Minimum ramp distance, the arc and linear move make up a quadrant of a circle that has a radius equal to the Minimum ramp distance.