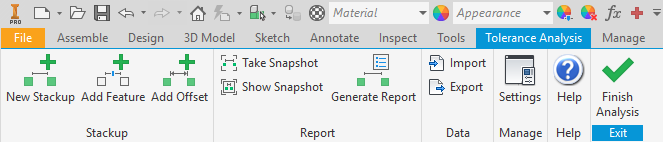

Click Tolerance Analysis on the Environments tab to enter the Tolerance Analysis environment. On the Tolerance Analysis tab, Manage panel, click Settings to open the dialog box, and specify the appropriate Default Tolerances.

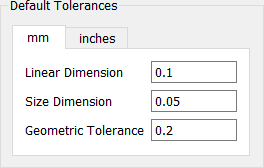

Default Tolerances

Specifies the defaults in Metric (SI) and US Customary (USC) systems of measurements. If a part in your assembly uses a different default unit of measure, the tolerances defined for the unit in the same system of measurement as the part unit are converted to the equivalent value in that part. For example, if one of the parts in the stackup uses cm, and the default tolerance for Linear Dimension on the mm tab is 0.1, then any linear dimensions defined in the part has a default tolerance of 0.01 cm. We recommend that you let Tolerance Analysis use the units defined in your CAD files to automatically manage unit differences in your models.

Symmetric ± tolerances are assumed for Linear and Size Dimensions.

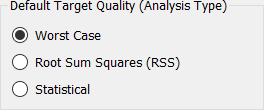

Default Target Quality (Analysis Type)

Specifies the default type of analysis that is used for each new stackup definition. Each stackup definition can be changed after it is defined, so you should only change this setting if you typically perform RSS or more general Statistical analyses.

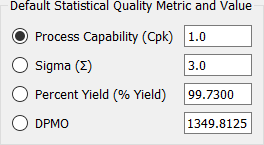

Default Statistical Quality Metric and Value

Specifies the quality metric most commonly used for your statistical analyses and the associated quality objective. You can change this setting for each stackup you define.

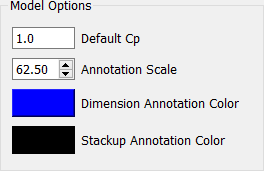

Model Options

Default Cp sets the default assumption defining the statistical distributions of each of the dimensions in the stackup.

The remaining entries define the scale and color properties of the tolerance annotations and dimensions used in the model and reports.