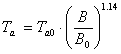

Maximum allowable belt working tension can be set up or it is calculated as follows

Specific belt weight is calculated as follows

T a0 , m 0 , B 0 , f max , v max are defined within belt XML data table as well as belt dimensions and available lengths and widths.

Belt power rating

P r = (k z T a - v m 2 ) v c L

Resultant service factor

![]()

Strength check fails if resultant service factor c Pr < c P .

Over-tensioning inspection

If F t max > F a or F t > F a the strength check fails as the maximum tension in belt span or static belt tension exceeded its maximum.

Recommended step if one of the criteria fails is increase belt width or driver pulley diameter. Also, the installation tension can be decreased if possible by decreasing belt tension factor k 1 . If number of teeth in mesh factor k z is less than 1.0 then consider to modify belt transmission layout.

Valid belt speed and flexing frequency inspection

If belt flex frequency f b > f max the reduced efficiency and premature belt damage might appear. The error warning is displayed.

If belt speed v > v max the error warning is displayed as the belt is not designed for such speed.

Meaning of used variables:

|

T a0 |

Maximum allowable belt working tension for base width [N] |

|

B |

Belt width [m] |

|

B 0 |

Belt base width [m] |

|

m 0 |

Specific belt width for base width [kg/m] |

|

k Z |

Teeth in mesh factor [-] |

|

T a |

Maximum allowable belt working tension for given width [N] |

|

m |

Specific belt weight for given width [kg/m] |

|

v |

Belt speed [m/s] |

|

c L |

Belt length correction factor [-] |

|

P R |

Belt power rating for given transmission layout [W] |

|

P |

power to transmit [W] |