Solid Element Orthotropic Material Property Generation

Description: Specifies the material properties for the generation of a solid element orthotropic material using MCT or Halpin-Tsai theory.

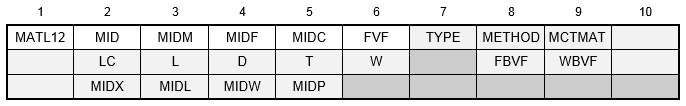

Format:

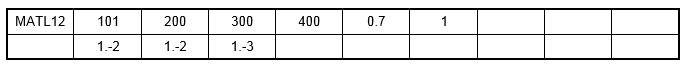

Example:

| Field | Definition | Type | Default | ||||||

|---|---|---|---|---|---|---|---|---|---|

| MID | Material identification number. Referenced on a PSOLID or PCOMP entry only. | Integer > 0 | Required | ||||||

| MIDM | Material identification number for the matrix material. See Remark 3. | Integer > 0 | Required if METHOD = 1 | ||||||

| MIDF | Material identification number for the reinforcement (fiber) material. See Remark 3. | Integer > 0 | Required if METHOD = 1 | ||||||

| MIDC | Material identification number for the composite material. See Remark 3. | Integer > 0 | Required if METHOD = 2 | ||||||

| FVF | Volume fraction of fiber. | 0.3 ≤ Real ≤ 0.9 | Required | ||||||

| TYPE | Reinforcement type, selected by one of the following values:

|

Integer | 1 | ||||||

| METHOD | Calculation method, selected by one of the following values:

|

Integer | 1 | ||||||

| MCTMAT | MCT material input, selected by one of the following values:

|

Integer | 1 | ||||||

| LC | Short fiber critical length. | Real > 0.0 | Required if TYPE = 3 | ||||||

| L | Fiber length. | Real > 0.0 | Required if TYPE = 3, 4, or, 5 | ||||||

| D | Fiber diameter. | Real > 0.0 | Required if TYPE = 3 or 5 | ||||||

| T | Fiber plate thickness. | Real > 0.0 | Required if TYPE = 4 | ||||||

| W | Fiber plate width. | Real > 0.0 | Required if TYPE = 4 | ||||||

| FBVF | Fill bundle volume fraction. See Remark 8. | 0.2 ≤ Real ≤ 0.37 | Required if TYPE = 6 | ||||||

| WBVF | Warp bundle volume fraction. See Remark 8. | 0.2 ≤ Real ≤ 0.37 | FBVF | ||||||

| MIDX | Material identification number for the MCT fill-matrix material. See Remark 3. | Integer > 0 | Required if TYPE = 6 and MCTMAT = 2 | ||||||

| MIDL | Material identification number for the MCT fill material. See Remark 3. | Integer > 0 | Required if TYPE = 6 and MCTMAT = 2 | ||||||

| MIDW | Material identification number for the MCT warp material. See Remark 3. | Integer > 0 | Required if TYPE = 6 and MCTMAT = 2 | ||||||

| MIDP | Material identification number for the MCT matrix-pocket material. See Remark 3. | Integer > 0 | Required if TYPE = 6 and MCTMAT = 2 |

Remarks:

- The material identification number must be unique for all MATi entries.

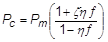

- The Halpin-Tsai method is based on a set of empirical relationships that enable the property of a composite material to be expressed in terms of the properties of the matrix and reinforcing phases together with their proportions and geometry. These equations were curve fitted to exact elasticity solutions and confirmed by experimental measurements. The parameter

depends on the particular elastic property being considered. Halpin-Tsai theory shows that the property of a composite

depends on the particular elastic property being considered. Halpin-Tsai theory shows that the property of a composite

can be expressed in terms of the corresponding property of the matrix

can be expressed in terms of the corresponding property of the matrix

and the reinforcing phase (or fiber)

and the reinforcing phase (or fiber)

using

using

The MCT (Multicontinuum Theory) method is a multiscale approach to composites analysis. Failure in the composite lamina is calculated by evaluating the stress state in either the fiber or matrix, rather than the homogenized composite lamina, allowing one to capture interactions between the two. The method is applicable to unidirectional and woven composites. High fidelity micromechanics models enable the generation/optimization of composite properties from properties of the matrix and fiber. MCT ply failure analysis is enabled by specifying MCT in the FT field of the PCOMP entry.

- MIDM and MIDF may reference a

MAT1,

MAT8, or

MAT12 entry for the Halpin-Tsai method and only a MAT8 or MAT12 entry for the MCT method. For MAT1 entries the E, G, and NU fields must be non-zero. The RHO, A, ST, SC, and SS fields are optional. For MAT8 entries the E1, E2, NU12, and G12 fields must be non-zero. The RHO, A1, A2, Xt, Xc, Yt, Yc, and S fields are optional. For MAT12 entries the E1, E2, E3, NU12, NU23, NU31, G12, G23, and G31 fields must be non-zero. The RHO, A1, A2, A3, Xt, Xc, Yt, Yc, Zt, Zc, S12, S23, and S31 fields are optional. MIDC is required for the MCT method and optional for Halpin-Tsai. MIDC, MIDX, MIDL, MIDW, and MIDP must reference a MAT8 or MAT12 entry only. MIDC specifies properties for the generated MAT12 material that are not calculated. The tables below lists what orthotropic material properties are generated based on the fiber type selected for the Halpin-Tsai and MCT methods.

Halpin-Tsai Generated Orthotropic Material Property Output

TYPE E1 E2 NU12 G12 RHO A1 A2 Xt Xc Yt Yc S 1 ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ 2 ✓ ✓ ✓ ✓ ✓ ✓ ✓ 3 ✓ ✓ ✓ ✓ ✓ ✓ ✓ 4 ✓ ✓ ✓ ✓ ✓ ✓ ✓ 5 ✓ ✓ ✓ ✓ ✓ ✓ ✓ MCT Generated Orthotropic Material Property Output

TYPE E1 E2 E3 NU12 NU23 NU31 G12 G23 G31 RHO 1 ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ 6 ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ MCT Generated Orthotropic Material Property Output

TYPE A1 A2 A3 Xt Xc Yt Yc Zt Zc S12 S23 S31 1 ✓ ✓ ✓ 6 ✓ ✓ ✓ The material allowables (Xt, Xc, Yt, etc.) must be specified on the MAT8 referenced by MIDC if failure index/strength ratios are desired and

- METHOD = 1 and TYPE ≠ 1

- METHOD = 2

- The TYPE field defines the fiber type. TYPE = 1 - 5 are applicable to Halpin-Tsai (METHOD = 1). TYPE = 1 or 6 is applicable to MCT (METHOD = 2). Fiber types are detailed in the following table.

TYPE Description Example 1 Aligned continuous fiber composite lamina. Individual continuous fibers oriented in a defined direction. Unidirectional graphite fibers in an epoxy resin. 2 Spherical particle composite lamina. Particulate composite consisting of an aggregate material with roughly round filler particles. Unreinforced concrete with a cement aggregate and sand filler. 3 Oriented short fiber composite lamina. Discontinuous short fibers oriented in a defined direction. A glass fiber reinforced polymer. 4 Oriented plate composite lamina. Particulate composite consisting of an aggregate material with a flat filler sheet. A phenolic thermoset polymer matrix with a glass filler. 5 Oriented whisker composite lamina. Discontinuous whisker-shaped fibers oriented in a defined direction. SiC whisker-reinforced ceramic matrix composite. 6 Plain weave composite lamina. Woven fabric where fill and warp threads interlace alternately resulting in equal properties in each direction. Graphite cloth in an epoxy resin. - The continuation entry is required based on TYPE and METHOD. For MCT (METHOD = 2), no continuation is required. For Halpin-Tsai (METHOD = 1), fiber parameters are required based on TYPE as shown below.

TYPE FVF LC L D T W 1 ✓ 2 ✓ 3 ✓ ✓ ✓ ✓ 4 ✓ ✓ ✓ ✓ 5 ✓ ✓ ✓ 6 ✓ - The MCTMAT field is only applicable for MCT (METHOD = 2) and affects how material properties specified on MIDM, MIDF, and MIDC are processed. When MCTMAT is set to 1 (default), MIDM and MIDF properties are optimized using a very high fidelity micromechanics model resulting in generated MIDC values. When MCTMAT is set to 2, the MIDM, MIDF, and MIDC values are assumed already optimized and no adjustment in values is made. MCTMAT set to 3, 4, or 5 provide optimized default values for common materials.

- MCT default material properties (MCTMAT = 3, 4, or 5) require that PARAM, UNITS be specified for the correct selection of default material units corresponding to the model input material property units (see Section 5, Parameters, for more information on UNITS).

- Material stability requires that if FBVF ≠ WBVF, then FBVF + WBVF ≤ 0.68. If this condition is not met, a fatal error will be issued.

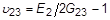

- MCT (METHOD = 2) with aligned continuous fibers (TYPE = 1) requires that the orthotropic material referenced by MIDC be transversely isotropic where

- MCT default fiber and matrix material properties (MCTMAT = 3, 4, or 5) are listed in the following table in metric units.

Variable Carbon Fiber Glass Fiber Kevlar Fiber Epoxy (Carbon) Epoxy (Glass) Epoxy (Kevlar) E1 2.3E+11 Pa

3.3E+7 psi

8.0E+10 Pa

1.2E+7 psi

1.2E+11 Pa

1.7E+7 psi

3.5E+9 Pa

5.1E+5 psi

3.3E+9 Pa

4.9E+5 psi

3.5E+9 Pa

5.1E+5 psi

E2 1.5E+10 Pa

2.2E+6 psi

8.0E+10 Pa

1.2E+7 psi

6.9E+9 Pa

1.0E+6 psi

3.5E+9 Pa

5.1E+5 psi

3.3E+9 Pa

4.9E+5 psi

3.5E+9 Pa

5.1E+5 psi

E3 1.5E+10 Pa

2.2E+6 psi

8.0E+10 Pa

1.2E+7 psi

6.9E+9 Pa

1.0E+6 psi

3.5E+9 Pa

5.1E+5 psi

3.3E+9 Pa

4.9E+5 psi

3.5E+9 Pa

5.1E+5 psi

G12 1.5E+10 Pa

2.2E+6 psi

3.3E+10 Pa

4.8E+6 psi

2.8E+9 Pa

4.1E+5 psi

1.3E+9 Pa

1.9E+5 psi

1.2E+9 Pa

1.8E+5 psi

1.3E+9 Pa

1.9E+5 psi

G13 1.5E+10 Pa

2.2E+6 psi

3.3E+10 Pa

4.8E+6 psi

2.8E+9 Pa

4.1E+5 psi

1.3E+9 Pa

1.9E+5 psi

1.2E+9 Pa

1.8E+5 psi

1.3E+9 Pa

1.9E+5 psi

G23 6.3E+9 Pa

9.1E+6 psi

3.3E+10 Pa

4.8E+6 psi

2.8E+9 Pa

4.1E+5 psi

1.3E+9 Pa

1.9E+5 psi

1.2E+9 Pa

1.8E+5 psi

1.3E+9 Pa

1.9E+5 psi

NU12 0.20

0.20

0.36

0.35

0.35

0.35

NU23 0.20

0.20

0.36

0.35

0.35

0.35

NU31 0.01

0.20

0.01

0.35

0.35

0.35

A1 -5.5E-7 / ° C

-3.1E-7 / ° F

4.9E-6 / ° C

2.7E-6 / ° F

-5.0E-6 / ° C

-2.8E-6 / ° F

5.3E-5 / ° C

2.9E-5 / ° F

5.8E-5 / ° C

3.2E-5 / ° F

5.3E-5 / ° C

2.9E-5 / ° F

A2 1.0E-5 / ° C

5.6E-6 / ° F

4.9E-6 / ° C

2.7E-6 / ° F

4.1E-5 / ° C

2.3E-5 / ° F

5.3E-5 / ° C

2.9E-5 / ° F

5.8E-5 / ° C

3.2E-5 / ° F

5.3E-5 / ° C

2.9E-5 / ° F

A3 1.0E-5 / ° C

5.6E-6 / ° F

4.9E-6 / ° C

2.7E-6 / ° F

4.1E-5 / ° C

2.3E-5 / ° F

5.3E-5 / ° C

2.9E-5 / ° F

5.8E-5 / ° C

3.2E-5 / ° F

5.3E-5 / ° C

2.9E-5 / ° F

- The model parameters TSAI2MCT, TSAI2MCTFVF, and TSAI2MCTBVF can be used to automatically generate MATL12 entries for MCT failure analysis. The TSAI2MCT ON setting will attempt to determine the composite material fiber material when the composite material property values are within 10% of the values listed in the below table.

Variable Composite Properties with Aligned Continuous Fibers Composite Properties with Plain Weave Fabric Carbon Fiber Glass Fiber Kevlar Fiber Carbon Fiber Glass Fiber Kevlar Fiber FVF/BVF 0.6

0.52

0.6

0.373

0.373

0.373

E1 1.4E+11 Pa

2.0E+7 psi

4.3E+10 Pa

6.2E+6 psi

7.5E+10 Pa

1.1E+7 psi

5.2E+10 Pa

7.5E+6 psi

2.7E+10 Pa

3.9E+6 psi

2.8E+10 Pa

4.1E+6 psi

E2 8.0E+9 Pa

1.2E+6 psi

9.7E+9 Pa

1.4E+6 psi

5.5E+9 Pa

8.0E+5 psi

5.2E+10 Pa

7.5E+6 psi

2.7E+10 Pa

3.9E+6 psi

2.8E+10 Pa

4.8E+6 psi

E3 8.0E+9 Pa

1.2E+6 psi

9.7E+9 Pa

1.4E+6 psi

5.5E+9 Pa

8.0E+5 psi

8.2E+9 Pa

1.2E+6 psi

1.0E+10 Pa

1.5E+6 psi

5.8E+9 Pa

4.1E+6 psi

G12 3.9E+9 Pa

5.7E+5 psi

3.5E+9 Pa

5.1E+5 psi

2.0E+9 Pa

2.9E+5 psi

4.0E+9 Pa

5.8E+5 psi

4.6E+9 Pa

6.7E+5 psi

2.0E+9 Pa

2.9E+5 psi

G23 3.9E+9 Pa

5.7E+5 psi

3.5E+9 Pa

5.1E+5 psi

2.0E+9 Pa

2.9E+5 psi

2.7E+9 Pa

3.9E+5 psi

3.1E+9 Pa

4.5E+5 psi

1.9E+9 Pa

2.8E+5 psi

G31 2.9E+9 Pa

4.2E+5 psi

3.4E+9 Pa

4.9E+5 psi

2.0E+9 Pa

2.9E+5 psi

2.7E+9 Pa

3.9E+5 psi

3.1E+9 Pa

4.5E+5 psi

1.9E+9 Pa

2.8E+5 psi

NU12 0.26

0.26

0.36

0.072

0.12

0.1

NU23 0.26

0.26

0.36

0.4

0.36

0.45

NU31 0.38

0.42

0.37

0.4

0.36

0.45

A1 6.4E-8 / ° C

3.6E-8 / ° F

7.2E-6 / ° C

4.0E-6 / ° F

-3.9E-6 / ° C

-2.2E-6 / ° F

3.2E-6 / ° C

1.8E-6 / ° F

1.2E-5 / ° C

6.7E-6 / ° F

3.3E-6 / ° C

6.1E-6 / ° F

A2 3.3E-5 / ° C

1.8E-5 / ° F

3.5E-5 / ° C

1.9E-5 / ° F

5.4E-5 / ° C

3.0E-5 / ° F

3.2E-6 / ° C

1.8E-6 / ° F

1.2E-5 / ° C

6.7E-6 / ° F

3.3E-6 / ° C

1.8E-6 / ° F

A3 3.3E-5 / ° C

1.8E-5 / ° F

3.5E-5 / ° C

1.9E-5 / ° F

5.4E-5 / ° C

3.0E-5 / ° F

5.2E-5 / ° C

2.9E-6 / ° F

4.4E-5 / ° C

2.4E-6 / ° F

7.3E-5 / ° C

4.1E-6 / ° F

If TSAI2MCTFVF or TSAI2MCTBVF are specified, TSAI2MCT must be set to either CARBON, GLASS, or KEVLAR as required. TSAI2MCT requires PARAM, UNITS to be specified. See Section 5, Parameters, for more information on TSAI2MCT, TSAI2MCTFVF, and TSAI2MCTBVF.