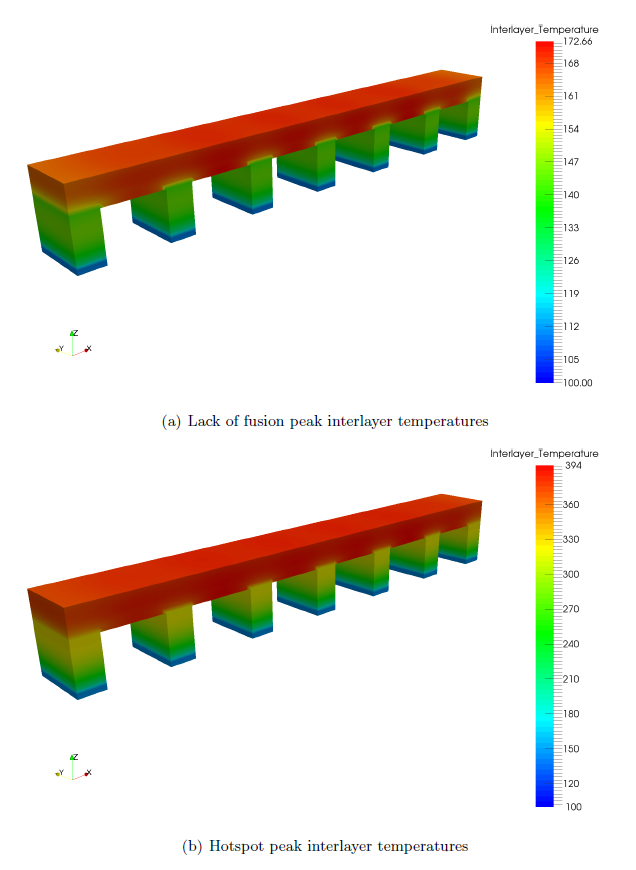

Figure 1 shows the peak interlayer temperatures from the two part scale simulations. The temperatures displayed are those after each layer of material is melted and the cool down period has completed. Observe how the hotspot case has much higher temperatures than the lack of fusion case. This will impact both the lack of fusion and hotspot behavior in each simulation, presented later.

Figure 1: Peak temperature results for lack of fusion and hotspot analyses, °C

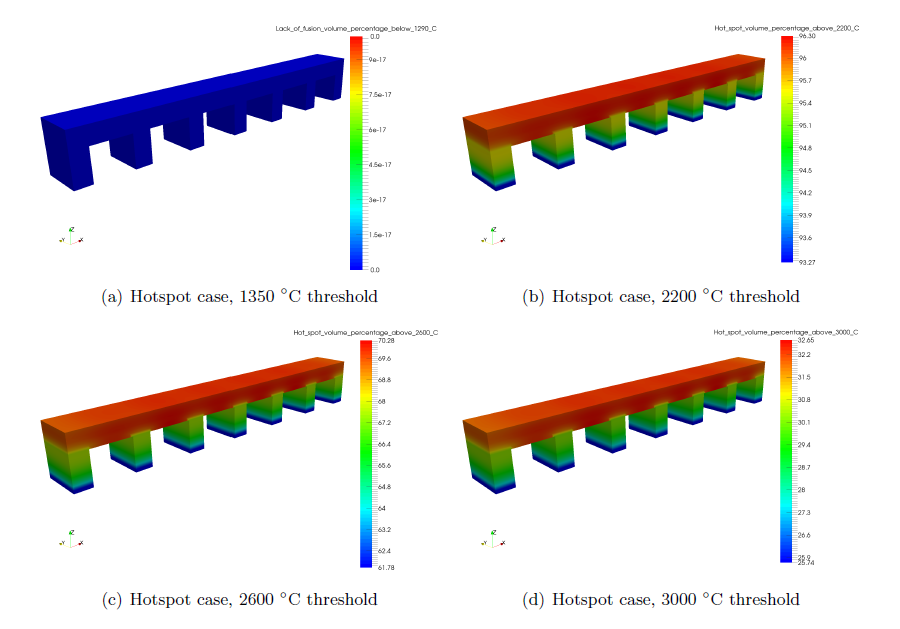

Figure 2 presents the lack of fusion case threshold results.

Figure 2: Lack of fusion case results

For this case, which intentionally used low heat input processing parameters, there is clear indication of lack of fusion problems. The minimum lack of fusion volume percentage for the 1290° C temperature is 20.3%. This indicates that more than 20% of the deposited volume does not even reach the solidus temperature, indicating there will be significant lack of fusion. The 1350° C check shows that over 28% of the build volume does not fully melt. This could cause lack of adhesion or build failure early on in the production of this part. Overheating is not an issue with this set of processing conditions, as a negligible portion of the build volume exceeds 2200° C, and none of the part reaches 2600° C.

Figure 3 presents the hotspot case results.

Figure 3: Hotspot case results

As expected, the hotspot results are opposite of the lack of fusion case. The part shows no lack of fusion problems, with all of the deposited part reaching the liquidus temperature of 1350° C. More than 93% of the part reaches at least 2200° C, more than 61% of the volume exceeds 2600° C, and more than 25% of the volume is heated over 3000° C. This shows these processing parameters create excessive heat. Hotspot reduction may be achieved by reducing the power input, increasing the interlayer dwell time, or adding support structures to draw heat away from the unconnected regions into the base plate.