Sample files for use with the examples are available from the Downloads page.

Expand the downloaded ZIP archive into a convenient directory from which to run Local Simulation inside the numbered directories.

Problem description

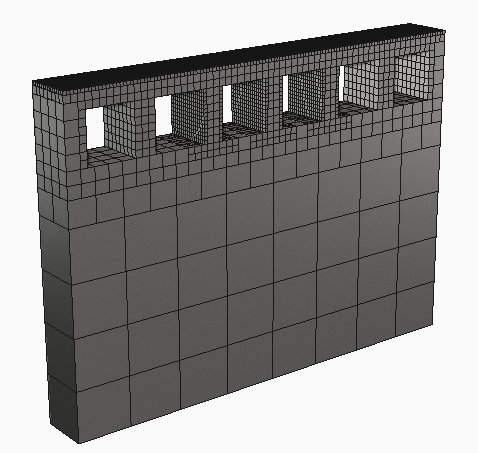

A generic geometry of Inconel 625 is built in a powder bed system and simulated. The layer height is 0.04 mm. The part geometry is imported in the analysis through an STL file, and it is automatically meshed by the Local Simulation solver. The substrate is assumed to be 38.1 mm thick. The resulting mesh is illustrated in Figure 1.

Figure 1: Autogenerated finite-element mesh

A time incremental thermal analysis is performed first to compute the temperature history of the part. Layers are activated in groups, and additional time increments are used to model heat conduction into the part. The thermal analysis includes only the part and substrate. Heat loss into the powder is modeled as convection with a value of 25.d-6 W/((mm2)°C) using the *CONV option.

Two time incremental mechanical analyses are performed after the thermal analysis is completed: one with qualitative stresses, one with quantitative stresses. Similarly to the thermal analysis, layers are activated in groups using *PBPA and the computed temperature distribution from the mechanical analysis is used to compute deformation due to the thermal expansion. The source PRM file is for Inconel 625, using generic processing parameters.