Thermal analysis

In the 05 directory, run the analysis from the command line:

$ pan -b 05_thermal

After the analysis completes, the last few lines of the output file 05_thermal.out should be similar to the following:

inc = 4149 time = 405.71173 iter = 1 eps = 0.61310E+02 inc = 4149 time = 405.71173 iter = 2 eps = 0.84002E+02 inc = 4149 time = 405.71173 iter = 3 eps = 0.31563E+01 inc = 4149 time = 405.71173 iter = 4 eps = 0.59223E-02 inc = 4149 time = 405.71173 iter = 5 eps = 0.20224E-04 Finished writing file results\ 05_thermal_4149.case Writing record: 83, time: 405.711732520632 Increment end CPU wall for increment 4150 = 00:00:00.07, since start = 00:08:46.32 Layer end Finished writing file .\ 05_thermal.case Analysis completed **************************** 1 Warning **************************** CPU wall = 00:08:46.39 Approximate single thread simulation time = 04:00:05.76 Peak RAM used for this process = 174,228 kB END Autodesk AM Process Simulation

Mechanical analysis

In the 05 directory, run the analysis from the command line:

$ pan -b 05_mechanical

After the analysis completes, the last few lines of the output file 05_mechanical.out should be similar to the following:

inc = 4285 time = 500.00000 iter = 1 eps = 0.70089E+05 inc = 4285 time = 500.00000 iter = 2 eps = 0.42054E+05 inc = 4285 time = 500.00000 iter = 3 eps = 0.50723E-09 Finished writing file results\ 05_mechanical_4285.case Increment end CPU wall for increment 4285 = 00:00:00.10, since start = 00:15:10.96 Layer end ------------------------------------------------------ Total number of equilibrium iterations: 23916 Finished writing file .\ 05_mechanical.case Analysis completed **************************** 1 Warning **************************** CPU wall = 00:15:11.40 Total thermal & mechanical simulation time = 00:23:57.79 Approximate single thread simulation time = 07:00:21.57 Peak RAM used for this process = 260,568 kB END Autodesk AM Process Simulation

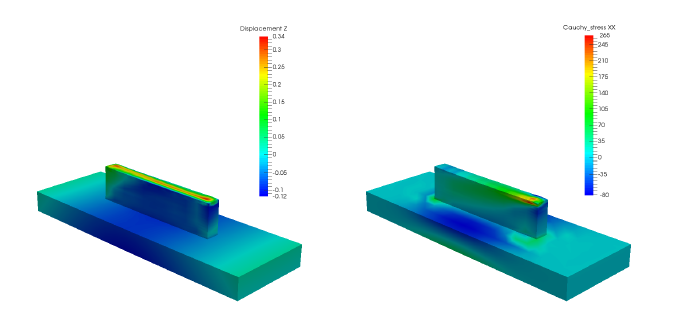

The results can be viewed in Simulation Utility for Netfabb or ParaView by importing the CASE files. Thermal results during deposition are shown at two different increments in Figure 3. Post-process distortion and a sample stress result is shown in Figure 4.

Figure 3: Temperature results (oC) at increments 1000 and 4000

Figure 4: (a) Post-process distortion results, warped, (b) Post-process XX direction Cauchy stresses, warped 1X