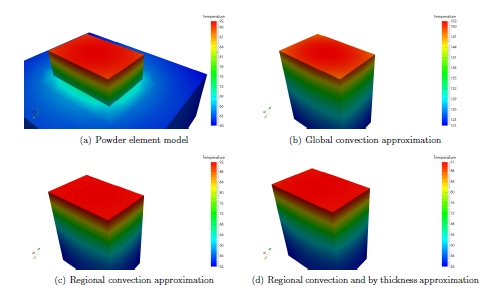

Figure 1 shows the thermal results at increment 20, where the thick base of the part is being modeled. Powder simulation results have had the powder elements removed for easier comparison with the non-powder cases.

Figure 1: Thermal results at increment 20

At this increment, the global heat flux approximation does not agree with the powder element analysis. However using the regional or the region plus by thickness convection approximations, the temperatures and gradients are nearly identical to the powder case. Now look at the thermal history at the end of the simulation, shown in Figure 2.

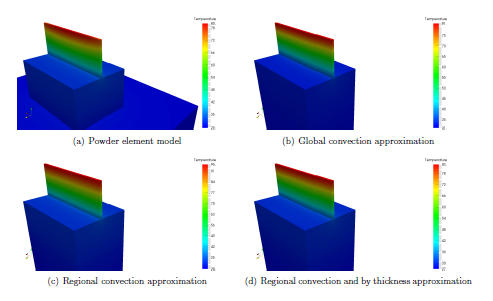

Figure 2: Thermal results at final increment

At this time step, the global convection value does match with the powder case very well. However the regional case, while very accurate for the thick section, allows the top section of the part to get hotter than the powder case predicts. Using the thickness-based convection corrects for this, bringing the temperatures very close to the powder case for both the thick and thin sections, while taking roughly 1/3 as long to complete.