Use the Feature face milling page to specify the feature face machining parameters.

XY expansion — Enter an allowance in the X and Y directions on the block. This is useful where the actual stock is larger than the PowerMill block as it ensures that the face milling toolpath machines all of the stock.

Engagement feed rate (%) — Enter a value to control the feed rate of the toolpath, as it approaches the block, until it fully engages with the block. This is useful to prevent tool inserts from breaking when they plunge into the model with high feed rate. By default this is set to 100% so there is no engagement feed rate reduction.

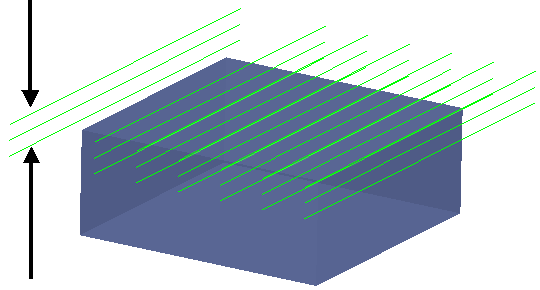

- Cutting feed rate

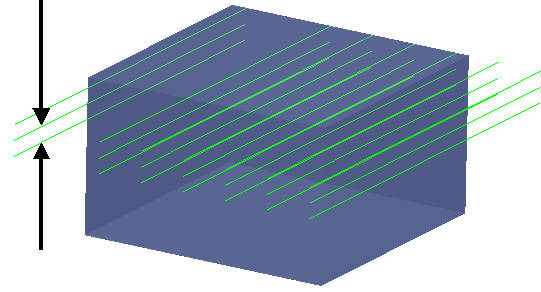

- Cutting feed rate

- Engagement feed rate

- Engagement feed rate

- Plunging feed rate

- Plunging feed rate

Tolerance — Enter a value to determine how closely the toolpath follows the feature.

Style — Select the Raster or Offset style to use for removing material.

Stepover — Enter the distance between successive machining passes.

Copy stepover from tool — Click to load the radial depth of cut from the active

tool's cutting data. The radial depth of cut is measured normal to the tool axis.

Copy stepover from tool — Click to load the radial depth of cut from the active

tool's cutting data. The radial depth of cut is measured normal to the tool axis.

.

.

Stepdown

Stock depth — Enter the total depth of material to remove.

Stepdown — Enter the maximum distance between successive passes.

Copy stepdown from tool

— Click to load the axial depth of cut from the active

tool's cutting data. The axial depth of cut is measured along the tool axis.

Copy stepdown from tool

— Click to load the axial depth of cut from the active

tool's cutting data. The axial depth of cut is measured along the tool axis.

.

.