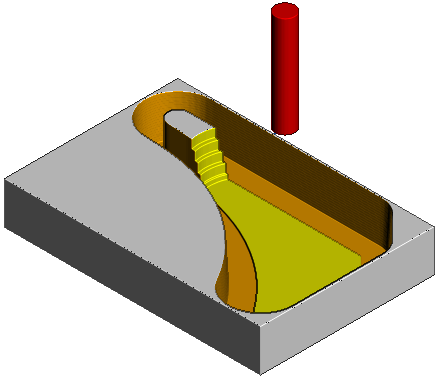

This example shows you how to avoid machining too far into the stock material. This prevents tool damage by controlling the depth of cut into the stock model. This uses the powerdrill.dgk model in the Examples file.

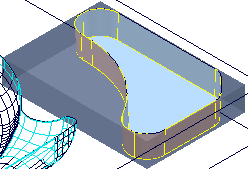

- Create a block around the pocket.

- Create a model area clearance toolpath using a 30 mm end mill.

- From the Stock Models context menu, select Create Stock Model.

- From the individual stock model context menu, select Apply > Active Toolpath Last.

- From the individual stock model context menu, select Calculate.

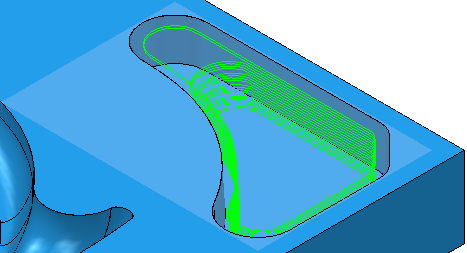

- Create a constant Z toolpath with a 10 mm end mill. On the Stock Engagement page:

- Select a Depth of cut and enter a

of 2.0.

of 2.0. - Select the Stock Model you have just created.

- Click Calculate.

It is easier to see the toolpath without the stock model.

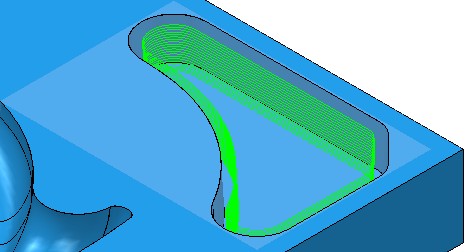

Looking at the ViewMill simulation:

You can see how the toolpath follows the stock model rather than the model.

- Select a Depth of cut and enter a

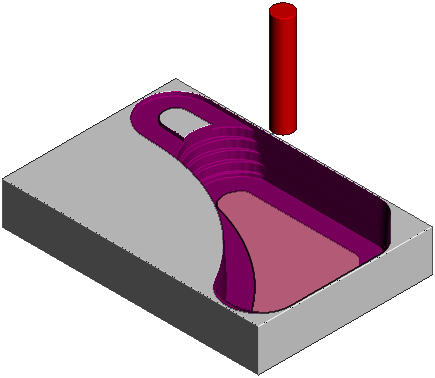

If you do not control the stock engagement, the toolpath follows the model rather than the stock.

- On the Strategy dialog click

to create a second constant Z toolpath based on this one.

to create a second constant Z toolpath based on this one. - On the Stock Engagement page:

- Select a Stock Model of none.

- Click Calculate.

Looking at the ViewMill simulation:

This toolpath generates an excessive depth of cut and tool load as it machines around the tight corner leaving the upstand in the middle.