Use the Feature chamfer milling page to specify the cutting range in the axial and radial directions of the tool.

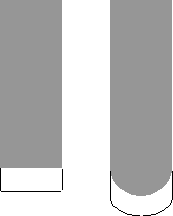

Axial

Multiple cuts are generated along the axial direction.

Limit defined by the block, the chamfer feature or the number of cuts.

Limit defined by the block, the chamfer feature or the number of cuts.

Stepdown

Stepdown

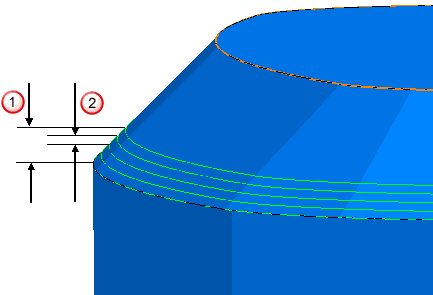

Extent — Select how to calculate the limits of multiple passes.

- Number of cuts — Enter a number to limit the number of passes.

- Chamfer extent — Machine the total height of the chamfer.

- Stock extent — Machine the distance between the tool start position and the end of the block.

Stepdown — Enter the maximum distance between successive passes.

Copy stepdown from tool

— Click to load the axial depth of cut from the active

tool's cutting data. The axial depth of cut is measured along the tool axis.

Copy stepdown from tool

— Click to load the axial depth of cut from the active

tool's cutting data. The axial depth of cut is measured along the tool axis.

.

.

Tool position — Select the position of the tool relative to the chamfer.

-

Top axial depth — The distance the tool extends above the top of the chamfer.

Top axial depth — The distance the tool extends above the top of the chamfer.

— Top axial depth

— Top axial depth

-

Bottom axial depth — The distance the tool extends below the bottom of the chamfer.

Bottom axial depth — The distance the tool extends below the bottom of the chamfer.

— Bottom axial depth

— Bottom axial depth

-

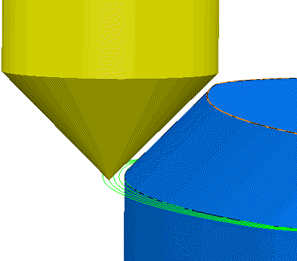

Gauge diameter — The effective tool diameter at the contact point of the tool on the chamfer.

Gauge diameter — The effective tool diameter at the contact point of the tool on the chamfer.

— Gauge diameter

— Gauge diameter

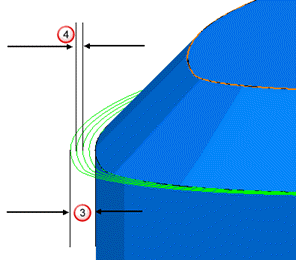

Radial

Multiple cuts are generated along the radial direction.

Limit defined by the block, the chamfer feature or the number of cuts.

Limit defined by the block, the chamfer feature or the number of cuts.

Stepover

Stepover

Extent — Select how to calculate the limits of multiple passes.

- Number of cuts — Enter a number to limit the number of passes.

- Chamfer extent — Machine the total width of the chamfer.

- Stock extent — Machine the distance between the tool start position and the end of the block.

Stepover — Enter the distance between successive area clearance passes at a single Z height.

Copy stepover from tool — Click to load the radial depth of cut from the active

tool's cutting data. The radial depth of cut is measured normal to the tool axis.

Copy stepover from tool — Click to load the radial depth of cut from the active

tool's cutting data. The radial depth of cut is measured normal to the tool axis.

.

.

Other options

Tolerance — Enter a tolerance value to determine how accurately the toolpath follows the feature.

Cut direction — Select the milling technology.

Select a Cut Direction from the following:

-

Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

-

Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling. This minimises the tool lifts and tool travel.

Thickness — Enter the amount of material to be left on the part. Click the

Thickness

button to separate the

Thickness

box in to

Radial thickness

button to separate the

Thickness

box in to

Radial thickness

Axial thickness

Axial thickness

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.