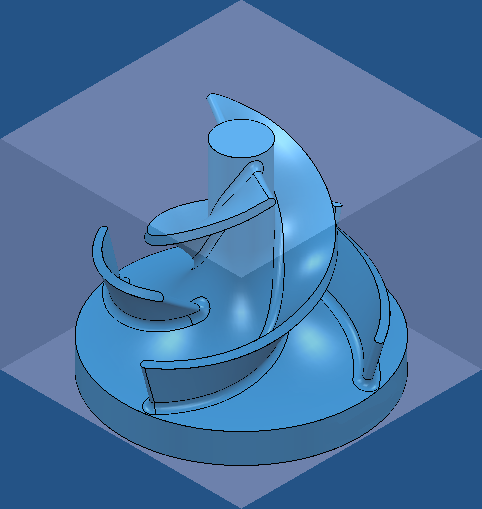

This example shows you how to use the Plunge Milling strategy using the Impeller.dgk model in the Examples folder.

- Calculate a

Block and create a

20 mm

End Mill Tool

.

.

- Create a

Raster Finishing Toolpath.

- From the

Stock Models

context menu, select

Create Stock Model.

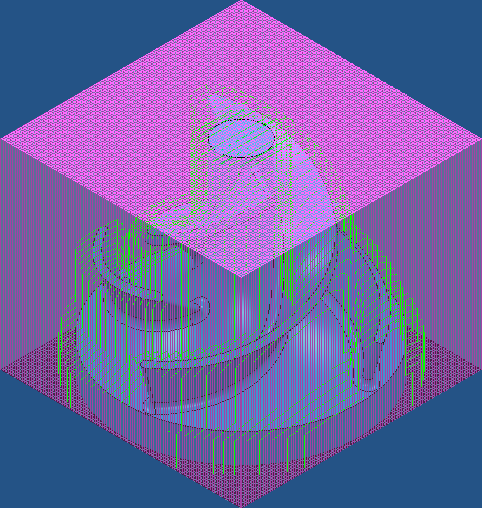

- From the individual stock model context menu, select Apply > Block.

- Expand the stock model, right-click

Block, and from the context menu, select

Calculate.

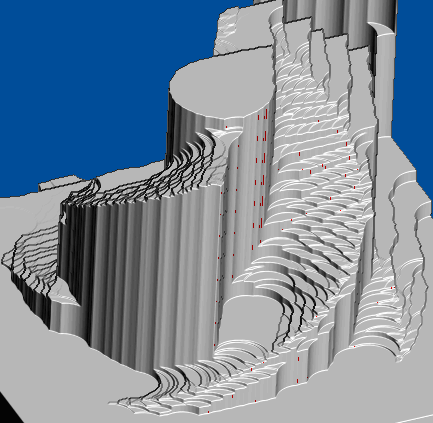

PowerMill creates a stock model of the block.

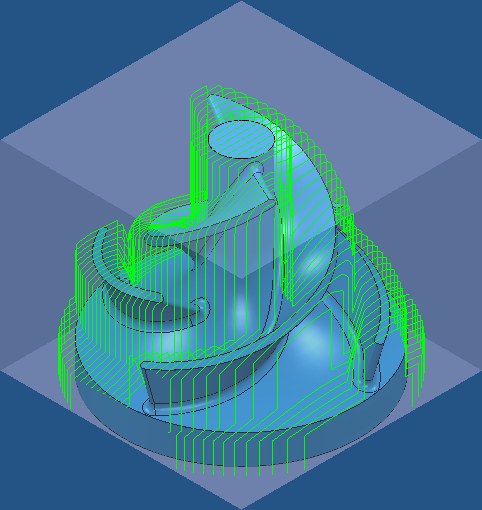

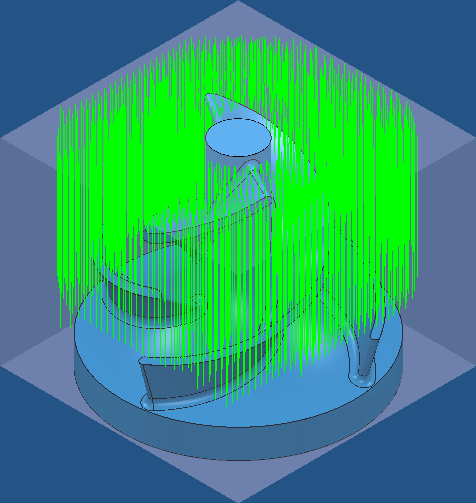

- Click Home tab > Create Toolpaths panel > Toolpaths to display the Strategy Selector dialog. From the 3D Area Clearance category, select Plunge Milling.

- In the Toolpath list select the Raster Finishing Toolpath created in step 2. This is used to act as a pattern for the Plunge Milling toolpath.

- In the Stock model list select the stock model created in step 3. This displays the un-machined stock so PowerMill can work out what material be removed.

- Enter a Core radius of 2. This defines the central portion of the tool where there are no cutting edges.

- Enter a Pullback distance of 0.5. This defines the distance that the tool pulls back away from the model to ensure that there are no dwell marks on the part or extraneous cutting moves added.

- Click

Apply to calculate the plunge milling toolpath.

Note: During plunge milling, the tool is placed under enormous stresses; this may cause the tool to be deflected. For this reason, it is often necessary to pull the tool back from the part at the end of each cutting move. This releases the stresses and the tool reverts to its original shape so you do not get any unexpected cutting moves.

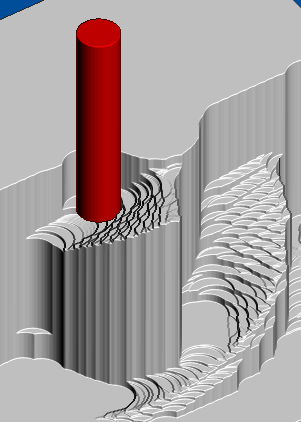

It is easier to view this toolpath using the ViewMill Simulation feature of PowerMill.

- From the Plunge Mill Toolpath context menu, select Simulate from Start. This displays the Simulation tab.

- Click Simulation tab > ViewMill panel > Off/On.

- Click Simulation tab > Simulation Controls > Play > Play to End.

This creates a rapid volume removal rate, but it is likely that you will need to follow a plunge milling toolpath with a rest roughing toolpath.