This example shows you how to combine Vortex machining with step cutting to rapidly remove material.

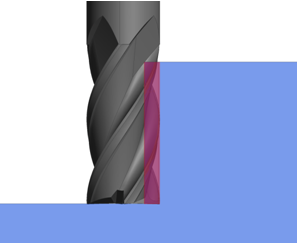

As Vortex machining cuts with the side of the tool, it is designed for solid carbide tools, but there may be other types of tools suitable for Vortex. These tools work best when taking deep cuts with a relatively small stepover.

To machine effectively when taking large depths of cut, you must ensure the tool engagement angle never exceeds the specified value. This eliminates excessive tool load and all full-width cuts. PowerMill achieves this by introducing trochoidal moves to prevent the tool from exceeding the maximum tool engagement value.

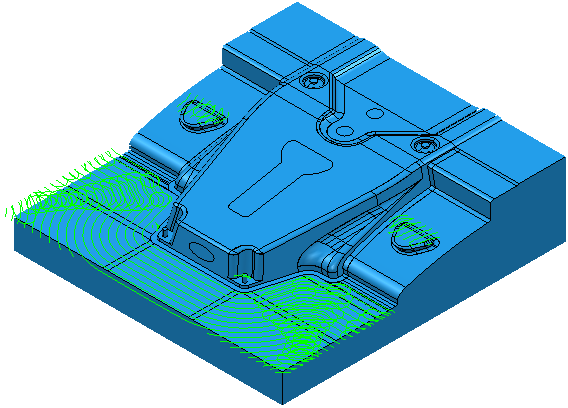

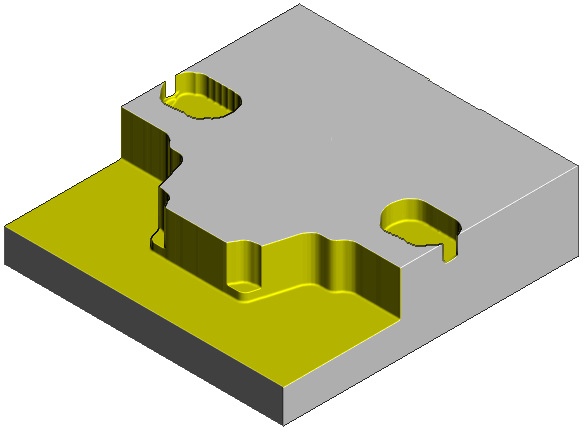

Using the Mould_Core.dgk model in the Examples folder.

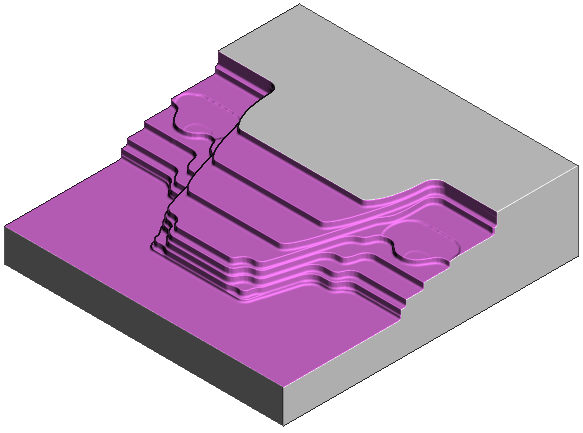

Creating a Vortex toolpath without step cutting.

This removes vast quantities of material quickly, but leaves large terraces of unmachined stock on the part.

You can minimise the size of these terraces using the Step cutting options.

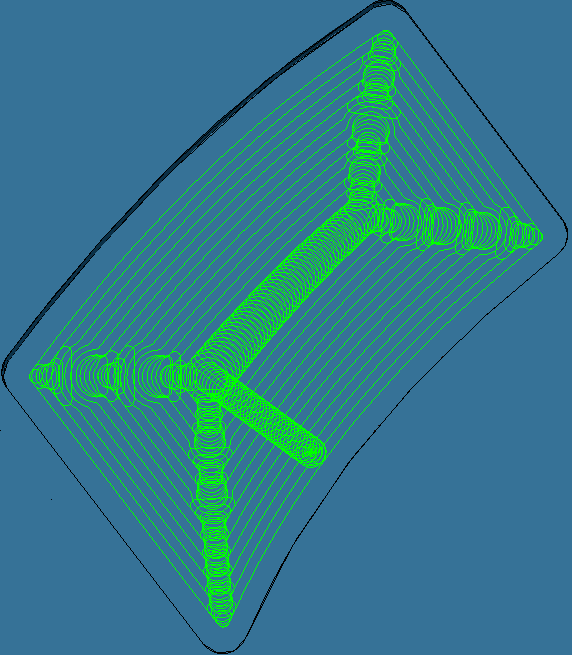

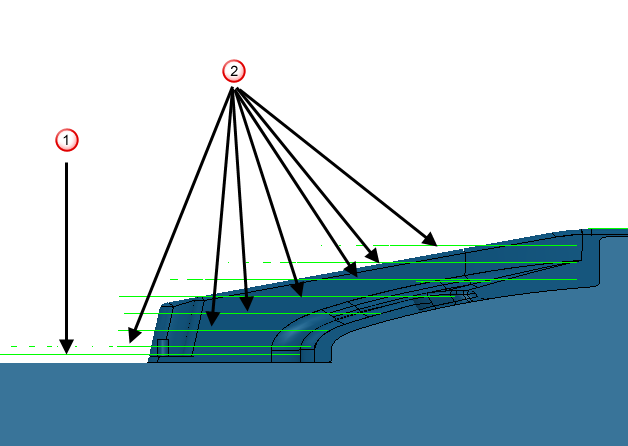

This adds extra machining slices up the part. Looking at a detail of the side view:

Original Vortex pass

Original Vortex pass

Step cutting passes

Step cutting passes

It also machines more of the excess stock.