Use the options on the Point distribution tab of the Toolpath connections dialog to control the point distribution along the leads and links. This is similar to the Point distribution options available for the toolpath cutting moves.

This tab contains the following settings

Apply to leads and links — Select to use the point distribution options used by the toolpath cutting moves for all the lead moves and the feed rate link moves. You specify the point distribution of the cutting moves on either the Point Distribution dialog or the Point distribution page of a strategy dialog.

Apply to rapid links — Select to specify the point distribution required for all the moves within a rapid link move. The rapid link moves are: Safe, Incremental, and Skim. The point distribution is applied to the plunge moves as well as the rapid moves within the rapid link.

- Copy from cutting moves — Click to copy the point distribution options used by the toolpath cutting moves to the rapid link moves.

Output point distribution — Controls the point distribution of the rapid link moves.

-

Output type — Select the type of point distribution in the rapid link moves. For diagrams of these options applied to cutting moves see

Point distribution > Output type

.

- Tolerance and keep arcs — Select to automatically remove unnecessary points in the rapid moves while maintaining tolerance. The points are not spaced equidistantly, as unnecessary points are deleted. Some of the points may be blue: these indicate the arc centres. The red points either side of the blue ones are the arc ends.

- Tolerance and replace arcs — Select to replace arcs with straight line segments and to remove unnecessary points in the rapid moves while maintaining tolerance. This is similar to Tolerance and Keep Arcs except that all arcs are replaced by straight line segments (polylines). This option is suitable for machine tools which don't handle arcs well.

- Redistribute — Select to allow the insertion of new points. This ensures a constant distance between points, only inserting extra points if they are necessary to keep tolerance. This can be especially useful when selecting the Point separation distance, or Point separation angle options. Redistribute may increase toolpath creation time but reduce time on the machine tool. This option is suitable for machine tools that can handle large numbers of equispaced points.

- Fit arcs — Select to produce rapid moves with arcs inserted wherever possible. This option is suitable for machine tools which handle arcs well, but is available only for 3-axis toolpaths.

- Tolerance factor — Enter a value to determine how many points are removed. This must have a value between 0 (removes a minimum number of points) and 1 (removes a maximum number of points while maintaining tolerance, so the rapid link moves contain the minimum number of points).

Point separation distance — Select to enter the maximum distance between rapid link move points.

- Maximum distance — Enter the maximum distance between consecutive rapid link move points.

Point separation angle — Select to enter the maximum change in angle between rapid link move points.

-

Maximum angle — Enter the maximum angle between consecutive rapid link move points. This is useful when approaching the gimbal lock position of your machine tool, where small angular changes can lead to large changes in the azimuth and elevation angles. To ensure the maximum angle is not exceeded,

PowerMill adds additional toolpath points, which slow the machine tool.

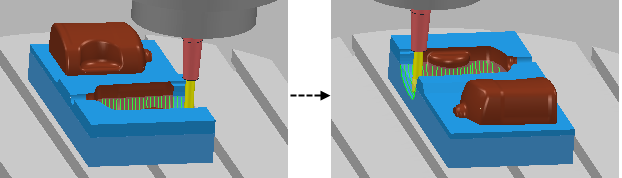

A gimbal lock is a specific configuration of a multi-axis machine tool that occurs when the tool axis aligns with at least one rotary axis due to the position of one or more toolpath points. This configuration results in undesirable movements because, when close to the gimbal lock, small adjustments in the tool axis can require large changes in a rotary axis. The graphic below shows the rotary axis of table-table machine tool (undesirably) rotating almost 180

in one second. This is because the machine tool machines a toolpath point at the bottom of the bottle cavity that coincides with the machine tool's gimbal lock.

in one second. This is because the machine tool machines a toolpath point at the bottom of the bottle cavity that coincides with the machine tool's gimbal lock.

Rotary axis configuration — Displays the current rotary axis configuration.

Gouge check — Select this option for PowerMill to gouge-check all leads and links.

Apply — Click to apply all the values in this dialog to the currently active toolpath.

Accept — Click to accept the values in this dialog and close the dialog. These values become the default values for the next toolpath calculation

Cancel — Click to close the dialog without updating the leads and links.