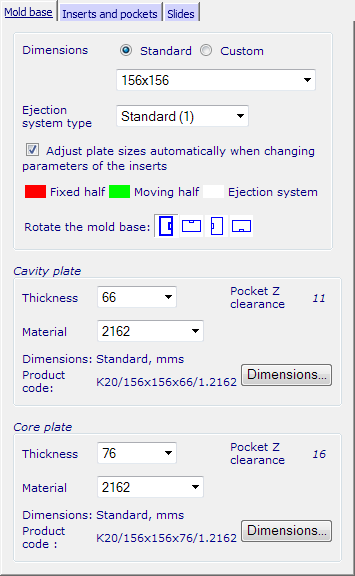

This tab defines the mold base.

Dimensions — The wizard has calculated the minimum size of the mold base to match the sizes of the inserts defined on the page. Check if the size is suitable and select a different size from the list if required.

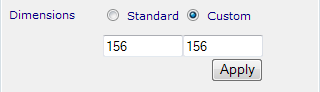

If you want to create a custom mold base, select the Custom option. Enter your dimensions and click Apply.

Ejector system type — Select the type of ejector system.

Adjust plate sizes automatically when changing parameters of the inserts — If on, the plates sizes will automatically change when you change the sizes of the inserts.

The fixed half is red; the moving half is green, and the ejector system is white (using the default colour scheme).

Rotate the mold base — You can rotate the mold to be created by 0 , 90

, 90 , 180

, 180 , or 270

, or 270 .

.

The default rotation is 0 . This conforms to the mold industry standard, that is, the width of the mold base is along the X axis and the length is along the Y axis.

. This conforms to the mold industry standard, that is, the width of the mold base is along the X axis and the length is along the Y axis.

Cavity/Core plate — Select the Thickness and Material of cavity/core plate. The Z clearance of the pocket is given on the right.

If you are using a standard mold base, values available from the catalogue can be selected from the drop-down lists.

For a custom mold base, you can type in the values

Dimensions — This tells you if the selected plate is standard or custom and its units. Click this button to change the dimensions of the selected plate. This displays a dialog that is similar to the page for defining the dimensions for components. For further details see Defining a component using the Component Wizard dialog.