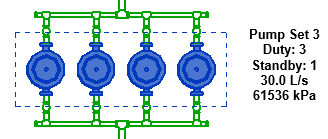

Create an mechanical equipment set when you want to utilize pumps operating in parallel conditions. To allow for more accurate pipe sizing, equivalent flow is calculated across two or more pumps, based on the number of on duty pumps in the set.

When you create a mechanical set, you can specify the number of on duty pumps and the number of pumps on standby. This information is used by the flow and pressure drop calculations for proper sizing of the branches and header of the pump set.

If the parallel pump set includes a header with caps at both ends, the flow along the entire length of the header is the same as the system flow. The header may be oversized by selecting only the components in the header and applying the sizing tool with a smaller velocity than is used in the rest of the system.

The Calculated Flow for the pump set matches the flow of the system. The Calculated Pressure Drop for the pump set is equal to the Calculated Pressure Drop of the pump branch piping critical path. Use the System Browser to view information about pump sets. Pump set information also displays in the pressure loss report for piping systems.

Before you create a pump set, be sure to enable analysis for closed loop hydronic piping networks in the Mechanical Settings dialog.

- In the drawing area, select a hydronic system that includes pumps that operate in parallel.

- Click the Modify | Mechanical Equipment Sets tab

System Tools panel

System Tools panel

Edit System.

Edit System.

- Click Edit Piping System tab

Parallel Set panel

Parallel Set panel

(Add).

(Add).

- In the drawing area, select two or more pumps to include in the pump set.

Note: The Classification parameter for each pump must be set to Pump in the Family Editor.

- If desired, specify the number of On Duty or On Standby pumps.

- Click

(Finish Editing System) to add the selected pump(s) or

(Finish Editing System) to add the selected pump(s) or

(Cancel Editing System) to discard the changes.

(Cancel Editing System) to discard the changes.

The selected pumps are added to the pump set.

- If desired, modify the number of pumps on duty and on standby. Select the pump set, and on the Properties palette, under Constraints, edit one of the values for On Duty or On Standby. Revit updates the corresponding value.

- If desired, edit the name of the pump set. Select the pump set, and on the Properties palette, under Identity Data, edit the Name.

When you create a pump set for the first time, or add pumps to an existing pump set (even if some are on standby), all pumps are on duty.

Remove pumps from a mechanical set when they are no longer needed. When you remove pumps from a set, you must leave at least two pumps in the set for it to remain valid.

- Click Edit Piping System tab

Parallel Set panel

Parallel Set panel

(Remove).

(Remove).

- In the drawing area, select one or more pumps that you want to remove from a parallel set.

When you remove a pump, all remaining pumps are on duty, even if some were previously on standby.