About the Transformer Rig

Compared to the Lattice Rig, the Transformer Rig tool is used for more controlled shape modifications driven by specific features of the model.

Custom modifiers and constraints

The Transformer Rig enables you to create custom modifiers specific to the model being changed. This provides tighter control of the surface modification.

The Transformer Rig also enables you to constrain parts of the selected target geometry. You can select real geometry to constrain the modifications, which makes the entire warp result more precise, and enables you to make finer-grained changes.

Flexibility

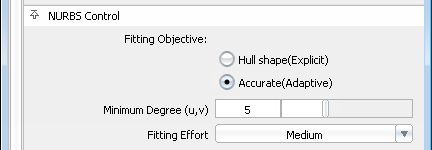

The Transformer Rig offers an additional NURBS fitting objective called Accurate.

Glossary of terms

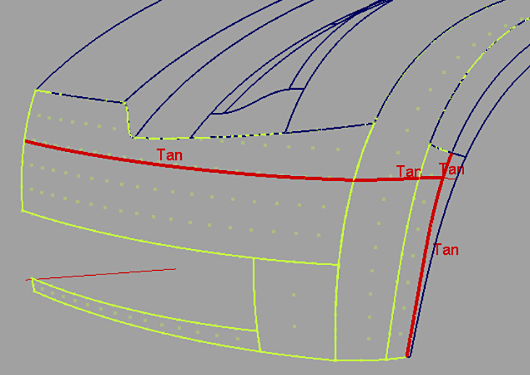

Constraints

To secure parts of the target geometry to prevent shape modifications, use constraints. Dynamic shape modeling analyzes the transformer rig and assumes that the constraints delimit a region of interest (ROI). Parts of the targets that lie outside of the ROI are clamped (they will not move). The estimate of the region of interest, however, is not always correct. If there are inaccuracies in the ROI, use clampers.

Clampers

Clampers are hints you place outside the intended region of interest to help the tool understand the desired ROI. Clampers help ensure that modifications don't happen outside the ROI.

Rigid targets

In some cases, there are geometries or objects within the target geometry that should keep their shape. Usually these are parts like buttons, door handles, and lights. These rigid targets are moved embedded in the flexible targets, but they do not lose their shape during the warp. Making a target rigid helps preserve the shapes of the parts while allowing them to move with the surface. Imagine grommets moving on a rubber tarp that is stretched to cover a load: the grommets remain the same shape and size on the flexible surface of the tarp.