About shells

Shells are a special type of surface or collection of surfaces you can use for special modeling operations, or for export to solid modeling packages.

Shells are collections of adjacent NURBS surfaces. Every surface stitched into a shell must meet the edge of another surface in the shell at some point.

Shells are stored as a single node in the DAG.

Shells can be open or closed. For closed shells, the normals should always point outward. This is necessary for the Boolean operations.

The main uses of shells are:

To improve data transfer to some CAD packages.

Some CAD packages deal with shells much better than normal trimmed NURBS surfaces.

To prepare for Boolean operations.

The Boolean tools (Shell subtract, Shell intersect, and Shell union) only work on shells. Often you simply stitch surfaces into shells, apply a boolean operation, then unstitch back into surfaces.

To check adjacencies between surfaces.

Surfaces can only be stitched into shells if they are within an adjacency tolerance.

If the tolerance is set correctly, you can easily check whether a group of surfaces will export or build properly by checking whether they stitch together into a shell.

To identify open edges in stitched shells:

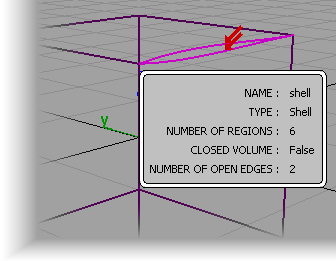

Use Object Edit > Query Edit

to check for open edges in shells. Red arrows clearly mark gaps in the shell.

to check for open edges in shells. Red arrows clearly mark gaps in the shell.

Shells have the following limitations:

Depending on the options in the Shell stitch option window, a stitched shell may not match the original surfaces exactly.

In this case, unstitching does not produce surfaces that match the originals exactly either.

You cannot edit CVs of a shell. If you need to reshape the surface of a shell, you must unstitch the shell.

You cannot use the isoparametric curves of shell surfaces as input for other tools.

You cannot maintain continuity with a shell in tools such as Square and Rail Surface.

You cannot create fillet surfaces on shells or between shells and other surfaces.

If you stitch an object, then scale it, then unstitch it, you not be able to restitch the object. This is because the scaling operation can increase the gaps between surfaces, thereby causing any subsequent stitch operations to fail (within the current tolerance settings). In this case, scale the object before you first stitch it.