|

|

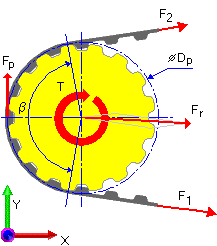

For each pulley |

|

F 2 - F 1 + F p = 0 |

|

|

|

|

|

|

|

|

|

For the driver pulley

![]()

|

|

v ≤ v max |

|

|

f b ≤ f max |

![]()

F c = mv 2

F Tmax = k 1 F p + F c

F 1 = F tmax

F 2 = F 1 - F p

For individual driven pulleys and idlers

i-index of the pulley

F Pi = P xi F p

![]()

![]()

![]()

F 1i = F 2i-1

F 2i = F 1i + F p i

where:

![]() for synchronous pulley

for synchronous pulley

![]() for flat pulley

for flat pulley

For entire belt drive

![]()

Required belt installation tension is determined from forces at driver pulley as follows

![]()

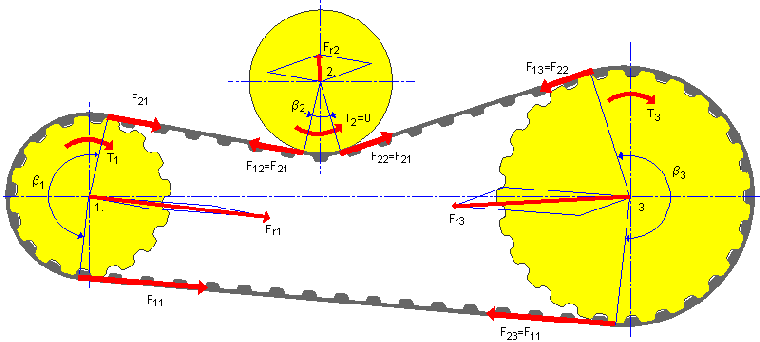

Example of power transmission with idler

|

Driver pulley |

Flat idler |

Driven pulley |

|

P x1 = 1 |

P x2 = 0 |

P x3 = 1 |

|

|

|

F P3 = P x3 F p |

|

|

|

|

|

|

|

|

|

|

F 12 = F 21 |

|

|

|

F 22 = F 12 + F p2 = F 12 |

|

|

F c = m v 2 |

|

|

|

F Tmax = k 1 F p + F C |

- |

F 13 = F 22 |

|

F 11 = F Tmax |

- |

F 23 = F 13 + F p3 = F 11 |

|

F 21 = F 11 - F p |

- |

|

|

|

- |

- |

Meaning of used variables:

|

F p |

Effective pull [N] |

|

F 1 |

Belt tension on input side of the given pulley [N] |

|

F 2 |

Belt tension on output side of the given pulley [N] |

|

z |

Number of teeth of given pulley/ Number of belt teeth [-] |

| β |

Arc of contact / tooth angle of side inclination [deg] |

|

P |

power to transmit [W] |

|

P R |

Belt power rating for given transmission layout [W] |

|

c L |

Service factor [-] |

| β |

Arc of contact [deg] |

|

T |

Torque acting on given pulley [Nm] |

|

n |

Speed of given pulley [rpm] |

|

D p |

Pitch pulley diameter [m] |

|

v |

Belt speed [m/s] |

|

k |

Number of pulleys within belt transmission [-] |

|

L |

Belt pitch length [m] |

|

P |

power to transmit [W] |

|

m |

Specific belt weight for given width [Kg/m] |

|

k 1 |

Belt tension factor [-] |

|

F p |

Effective pull [N] |

|

F c |

Centrifugal force [N] |

|

F t |

Minimum belt installation tension [N] |

|

P xi |

Power ratio of given pulley [-] |

|

D pi |

Pitch pulley diameter [m] |

|

i |

Transmission ratio (speed ratio) of given pulley [-] |

|

T i |

Torque acting on given pulley [Nm] |

| η |

Efficiency [-] |

|

p b |

Circular pitch [m] |

|

D |

Nominal flat pulley diameter [m] |

|

H |

Belt height [m] |

|

h T |

Belt tooth height [m] |

|

a |

Pitch line offset [m] |