Hollow Shaft

Solid Shaft

![]()

![]()

C 1 = C 1A + C 1B

Δ = p T D 1 C 1 + H

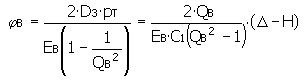

Minimum practicable interference

Minimum practicable interference is calculated from condition of required transmitted load. Smaller interference would not transfer required load.

|

|

or |

|

|

|

||

Maximum practicable interference

Maximum practicable interference is calculated from condition of material strength limit. Larger interference would cause hub or shaft material to be damaged.

|

Hub |

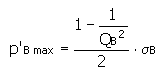

Shaft |

|

|

|

Hollow shaft

The following inequalities must be true:

Δ' max ≤ p' Amax D 1 C 1 + H

Δ' max ≤ p' Bmax D 1 C 1 + H

Solid shaft

The following inequalities must be true:

Δ' max ≤ p' Amax D 1 C 1 + H

Δ' max ≤σ B D 1 C 1 + H

The minimum interference from both inequalities is selected as the maximum interference.

The maximum and minimum interference

The calculation designs a fit according to the corresponding standards, such as ISO, ANSI, JIS, and others. The standard fit cannot exceed limits for maximum and minimum interference. The maximum and minimum interference intended for another calculation part is determined from the selected fit. If the corresponding fit cannot be selected, the deviations are numerically expressed and calculated by dividing the tolerance field into two halves.

Enlarging of outer diameter of external part

Δ' max ≤ p' Amax D 1 C 1 + H

Δ' max ≤σ B D 1 C 1 + H

The minimum interference from both inequalities is selected as the maximum interference.

Δ max is substituted for Δ when the maximum reduction of D 2 diameter is to be calculated

Δ min is substituted for Δ when the maximum reduction of D 2 diameter is to be calculated

Reducing the inner diameter of internal part

Δ max is substituted for Δ when the maximum reduction of D 3 diameter is to be calculated

Δ min is substituted for Δ when the maximum reduction of D 2 diameter is to be calculated

Calculating pressing force

Calculating heating temperature of outer part

Calculating heating temperature of internal part

![]()

Torque

M p = Fp D 1 /2

Meaning of used variables:

|

M p |

Torque |

|

E A |

Modulus of elasticity |

|

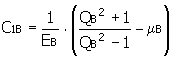

E B |

Modulus of elasticity |

|

μA |

Poisson's Ratio |

|

μB |

Poisson's Ratio |

|

D 1 |

Outer diameter of external part (hub) |

|

D 2 |

Pressure fit diameter (nominal diameter of calculated fit) |

|

D 3 |

Inner diameter of internal part (shaft) |

|

L |

Connection length |

|

F pmax |

Max. pressing force |

|

F pmin |

Min. pressing force |

|

k |

Safety factor |

| ν |

Clamping factor |

|

ν 1 |

Clamping factor during pressing |

|

σ A |

Thermal expansion of outer part (hub) |

|

σ B |

Thermal expansion of internal part (shaft) |

|

H |

Surface smoothness |

|

V |

Assembly clearance |

|

P max |

Max. contact pressure |

|

P min |

Min. contact pressure |

|

p' Tmin |

Minimum practicable contact pressure |

|

p Tmin |

Minimum practicable contact pressure |

|

p Tmax |

Maximum contact pressure |

|

p' Amax |

Allowable pressure on the hole of external part |

|

p' Bmax |

Allowable pressure on the hole of internal part |

| Δ |

Interference |

|

Δ' min |

Minimum practicable interference |

|

Δ' max |

Maximum practicable interference |

|

Δ min |

Minimum interference |

|

Δ max |

Maximum interference |

|

α A |

Factor of thermal expansion of external part material |

|

α B |

Factor of thermal expansion of internal part material |

|

t |

Basic temperature |