The size dimension must fall within the physical feature extents. The specified size dimension is outside the valid range for the feature.

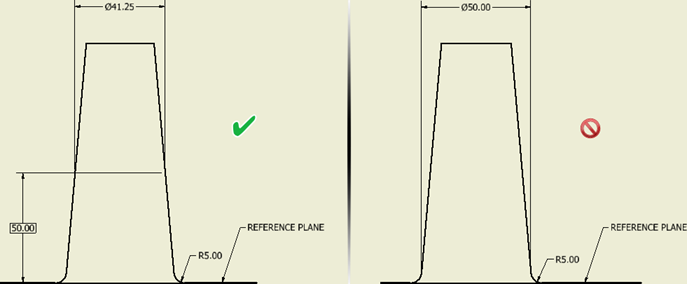

The following image shows an example of a tapered shaft with two different dimensioning schemes.

The scheme on the left is a valid method for defining the gage diameter of the feature.

The scheme on the right shows the gage diameter of the feature at the reference plane. However, there is a fillet between the feature and the reference plane. The fillet removes the edge where the diameter is specified and therefore falls outside the actual extents of the tapered shaft. It is poor practice to define the size at this location because the small fillet makes the diameter difficult to inspect.

To eliminate this problem, modify the parametric dimensioning scheme in the model for this feature.