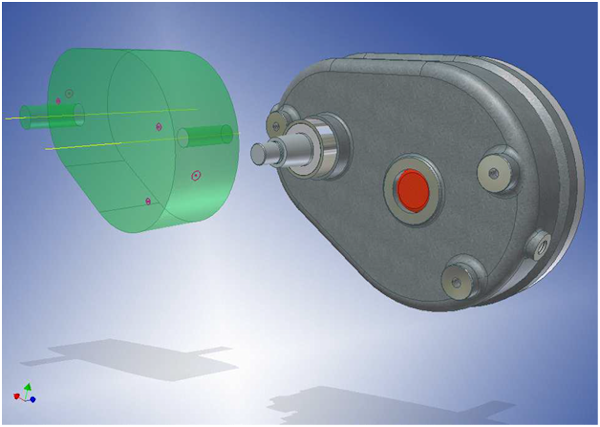

This method uses pre-determined workspaces to define the design criteria for components. Boundary surfaces, work geometry, or solids define the workspace. The workspace defines the size of components, position of components or connectors, keep-out areas, and other design considerations. Components are created inside the workspace using the envelope geometry where necessary.

Advantages

- Constraints are not dependent on component geometry. Therefore, changes to geometry do not affect constraints.

- The assembly can be easily split into smaller elements for collaboration.

- Better change management through modification of the workspace envelope

- Easy use of simplified components.

Disadvantages

- Data increase with creation of components with workspaces

Inventor commands

- Derived parts

- Adaptivity

- Copy Geometry