An assembly file has a Positional representation named Primary that represents the default state of the assembly. When creating a Positional representation, primary is copied.

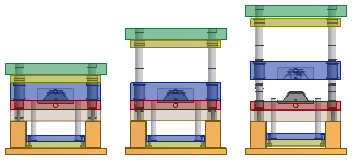

The following positional representations are created when inserting a mold base:

- Product open

- Ejection

- Close

- Free Drag

Use the positional representations to evaluate the mold base in various positions.

Note: The Representations folder is not available in the Mold Design browser view. Set the browser filter to either the Model or Representations browser to view the Representations folder. Expand the Position node to view the mold base positional representations.

- Open a top-level assembly that includes a current mold base.

- In the Model browser, select the Representations folder to expand.

- Right click the Position entry to create a positional representation, or right-click an existing one (not the primary positional representation), and select Activate.

The assembly reconfigures. Further edits to the model are suspended until the mold base Primary representation is activated.

- Examine the effect of the changes on the mold base and determine the adjustments required to accommodate the different positions:

- Check for interference.

- Check for clearance violations.

- Optionally, activate the Free Drag representation and enter the dynamic simulation environment for further mold analysis. All kinematic constraints are suppressed in the Free Drag representation.

- Activate the Primary positional representation and return to the top-level assembly to perform further edits and updates to the mold.

Note: Use Inventor Studio to animate a sequence of positional representations. Use positional representations as an Overlay view in a drawing to show the mold in different positions.