Troubleshooting jetting problems

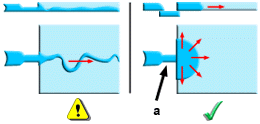

Jetting occurs when polymer melt is pushed at a high velocity through restrictive areas, such as the nozzle, runners, or gates; or into open, thicker areas, without forming contact with the mold wall.

The buckled, snake-like jetting stream causes contact points to form between the folds of melt in the jet, creating small scale welds.

Figure 1 Jetting

Jetting leads to part weakness, surface blemishes, and a multiplicity of internal defects.

Causes

- Excessive ram speed.

- Poor gate position. Lack of melt contact with the mold allows jetting to occur.

- Inadequate hot runner system design.

Remedies

Optimize gate design and position. Direct the melt against a metal surface by repositioning the gate or use an overlap or a submarine gate.

Use a tab or fan gate to slow down the melt with a gradually divergent flow area. This reduces the melt shear stress and shear rate.

Figure 2 Overlapping gate to minimise jetting. a overlapping gate.

Optimize the ram speed profile. Use an optimized ram speed profile so that melt front velocity is initially slow when the melt passes through the gate, then increases once a dispersed flow is achieved.

Solving one problem can often introduce other problems to the injection molding process. Each option hence requires consideration of all relevant aspects of the mold design specification.