Troubleshooting weld lines and meld lines

A weld or meld line on plastic parts can cause structural problems and/or be visibly unacceptable.

A weld or meld line is a weakness or visible flaw created when two or more flow paths meet during the filling process. Weld lines can be caused by material flowing around holes or inserts in the part, multiple injection gates or variable wall thickness where hesitation or "race tracking" can occur. If the different flow fronts have cooled before meeting, they don't interfuse well and can cause a weakness in the molded part. A line, notch and/or color change can appear.

Difference between weld and meld lines

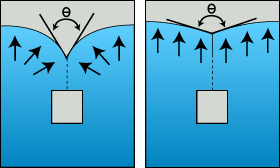

The difference between a weld and meld line is determined by the angle at which the converging flow fronts meet.

In the above diagram, the converging flow fronts (indicated by black arrows) meet. If the angle,  , is greater than 135° a meld line will form. If

, is greater than 135° a meld line will form. If  is less than 135° a weld line will form.

is less than 135° a weld line will form.

Weld lines

When a weld line forms, the thin frozen layers at the front of each flow path meet, melt, and then freeze again with the rest of the plastic. The orientation of the plastic at the weld is therefore perpendicular to the flow path. The following animation shows plastic filling a cavity. The weld line occurs where two flow fronts meet, and the polymer molecules are misaligned.

It is the sharp difference in molecular orientation at the weld which causes the significant decrease in strength at this point.

Meld lines

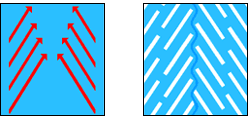

A meld line occurs when two flow fronts blend together at an oblique angle. The orientation of the plastic molecules is therefore more uniform than the orientation after a weld line has formed. The following diagram shows the length of a part where a meld line forms.

The red arrows show the direction of plastic flow. The white lines represent the orientation of the polymer molecules after the meld line has formed.

Meld lines are normally stronger than weld lines and are often much less visible.

Remedies

Weld and meld lines on a plastic part can cause structural problems and be visually unacceptable. (A line, notch and/or color change can appear.) Therefore weld and meld lines should be avoided if possible (when the cavity has unbalanced flow paths unnecessary weld and meld lines can occur).

If it is not possible to remove a weld/meld line, it should be positioned in the least sensitive area possible. Avoid weld lines in areas which need strength, or which need to appear smooth. This can be done by changing the polymer injection location or altering wall thicknesses to set up a different fill time. With a different fill time, flow fronts may meet at a different location and therefore the weld/meld line will move.

Moving:

- Change the gate positions.

- Change the part thickness.

Improving the quality:

- Increase melt and mold temperature. This will allow the flow fronts to interfuse more.

- Increase ram speed.

- Optimize runner system design. Reduce runner dimensions and maintain the same flow rate to use shear heating to increase the melt temperature at the flow front.

Solving one problem can often introduce other problems to the injection molding process. Each option requires consideration of all relevant aspects of the mold design specification.