Several temperature result types can be displayed, depending on the PRM type and operating conditions:

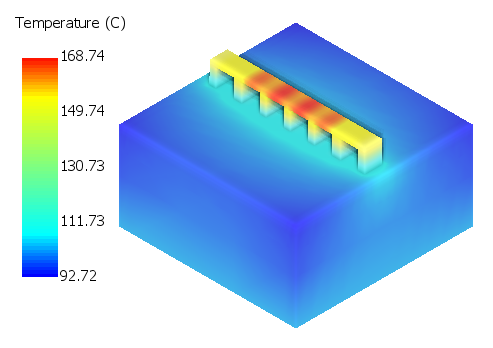

- Temperature - thermal results written during the mechanical response simulation. These correspond to the time after the powder layer has been deposited and the recoater has already swept the new layer across, right before the next layer is rastered.

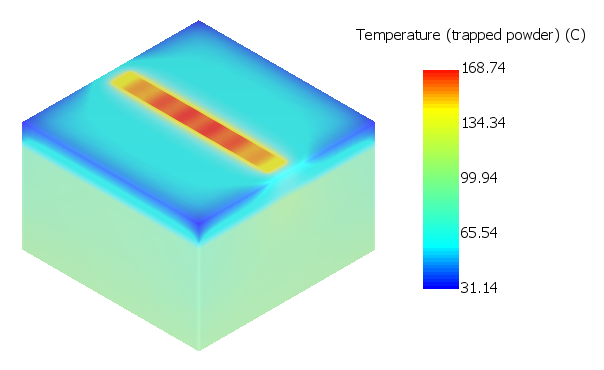

- Temperature (trapped powder) - thermal results of the thermal simulation which displays the powder elements in addition to the parts and supports. These only exist if

Conduction to loose powder has been selected on the

Operating Conditions panel. The time step is the same as the normal temperature results, right before each new layer is rastered.

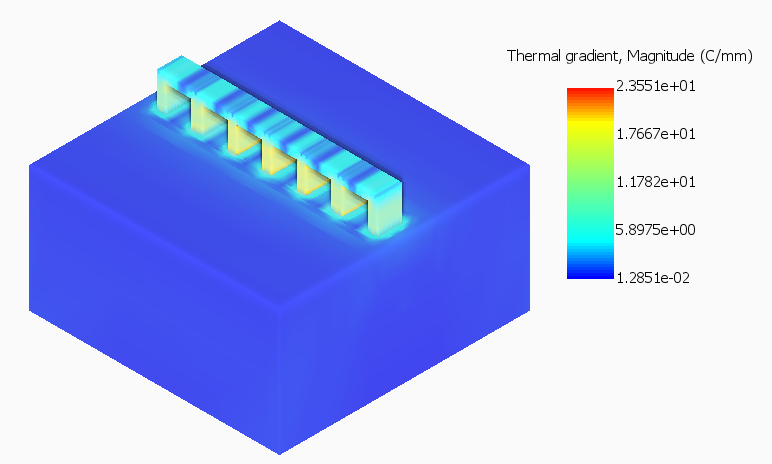

- Thermal gradient shows the change in temperature per unit length.

Lack of Fusion or Hot Spot analysis

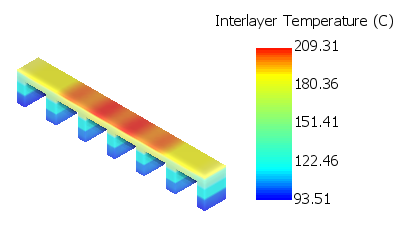

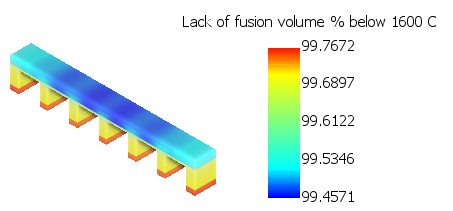

The figures below show three temperature results produced whenever a PRM file containing lack of fusion and/or hot spot information is used for a thermal or thermo-mechanical simulation. For more information on hot spot and lack of fusion settings, see New PRM File Creation.

- Interlayer temperature – This is a global, single increment result, which shows the modeled temperature between each layer, right before the subsequent layer is rastered.

- Lack of fusion volume % below <temperature> – This is a global, single increment result, which shows the possible percentage of each element that falls below the specified temperature, in Celsius, Fahrenheit, or Kelvin degrees. The example below is for the material Ti-6Al-4V.

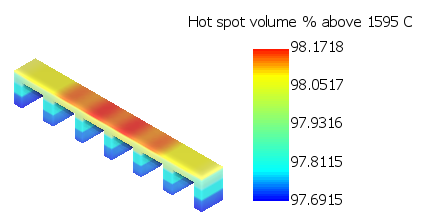

- Hot spot volume % above <temperature> – This is a global, single increment result, which shows the possible percentage of each element that exceeds the specified temperature, in C, F, or K degrees. The example below is for the material Inconel 625.