After manufacture, heat treat parts to relieve stress.

Video length (2:38).

In Local Simulation, users can add a heat treatment cycle to the end of a thermo-mechanical simulation to relieve stresses accumulated during manufacturing. This tutorial uses the material Inconel 625.

Sample files for use with the tutorials are available from the Downloads page. Expand the downloaded ZIP archive into a convenient directory from which you can import files into Local Simulation as you need them.

- In Local Simulation, click , browse to the sample folder Example_17, and open the model Example_17.tivus.

- On the

Home tab, click

Machine and check that

Processing parameters is set to

Inconel 625.

- Click .

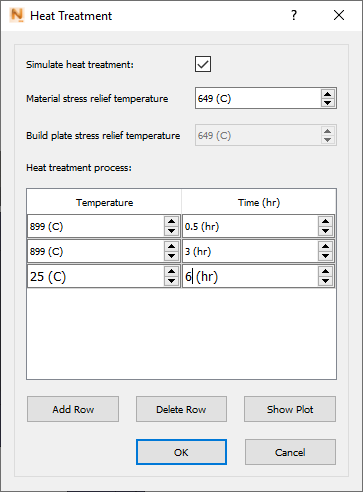

- In the dialog, select Simulate heat treatment, and set the Material stress relief temperature to 649 (C).

- In the

Heat Treatment process table, set the values shown:

The time value for a particular temperature phase indicates the elapsed time from the beginning of heat treatment to the end of that temperature phase. The system will check that the times are a series of increasing values.

- Click OK to close the Heat Treatment dialog, then click Solve.

- When the results are loaded, review the

Temperature results.

The Timeline along the bottom of the simulation window is very useful for following the stages of this simulation. A sample result:

- Printing, increments 1 through 8

- Cooldown, increment 9

- Plasticity, increment 10

- Heat treatment, increments 11 through 15

- Substrate removal, increment 16

You see temperatures increase through the deposition process, then cool down to room temperature. Temperatures increase again through the heat treatment phase, then cool slowly until build plate removal at the end. You may want to note the time in seconds when transitions occur so that you can compare these temperature events with the stress results at the same time. Remember that heat treatment occurs during increments 11 through 15 of the simulation.

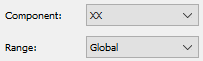

- Now view the

Cauchy stress results. On the

Results Settings tab, check that the

Component value is XX to focus on the longitudinal stress, and change the

Range setting to

Global.

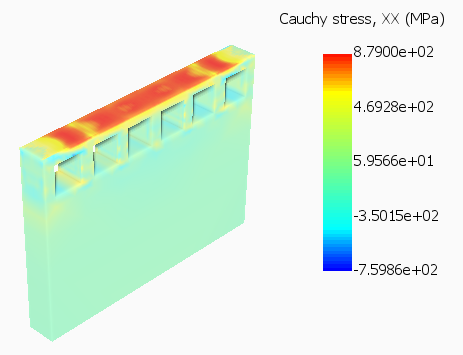

Maximum stress occurs in the first increment of heat treatment (shown below), then gradually relaxes.

- For a clearer view of the model, as shown above, in the Browser deselect Element Edges, located just below the Results folder.