Demonstrate how to work with 6-axis directed energy deposition (DED) and 6-axis laser (lsr) vector files.

Video length (3:27).

Sample files for use with the tutorials are available from the Downloads page. Expand the downloaded ZIP archive into a convenient directory from which you can import files into Local Simulation as you need them.

- In Simulation Utility, click

, then in the

Simulation Utility dialog, click

DED and

Create Simulation.

The Import model dialog opens.

- Browse to where you saved the Examples files, and in the Example_24 folder, open the file

6AxisPath.lsr.

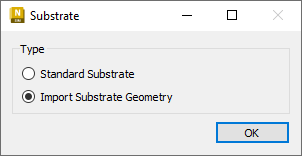

- In the Substrate dialog, select Import Substrate Geometry, and click OK.

- Browse again to the Example_24 folder, and open the file 6AxisSubstrate.stl.

- In the

Converted model units dialog, click

OK.

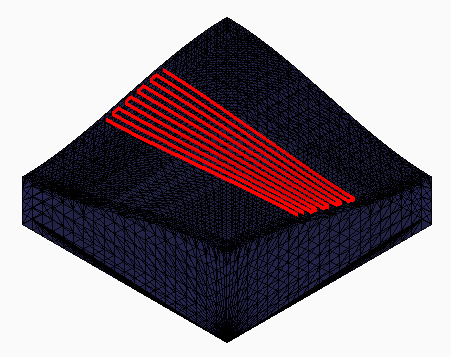

Upon import, observe the curved laser path on a double-curved substrate.

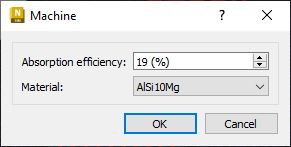

- On the

Home tab, click

Machine; set

Absorption efficiency to 19% and

Material to AlSi10Mg, then click

OK.

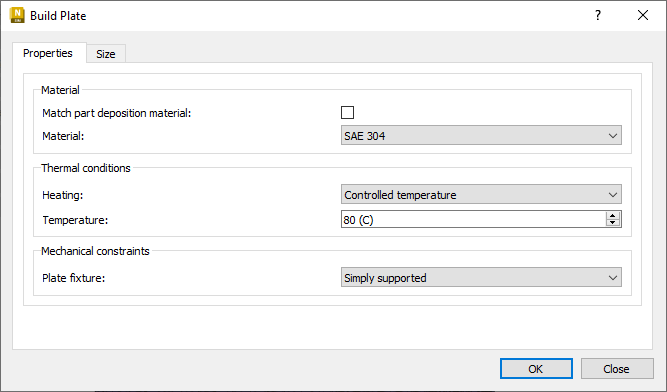

- Click

; deselect

Match part deposition material, and set

Material to SAE 304. Note that unlike standard DED simulations, with 6-axis DED simulations you can specify the substrate material.

- Also on the Properties tab, under Thermal conditions, Heating, set a Controlled temperature of 80° C, then click OK.

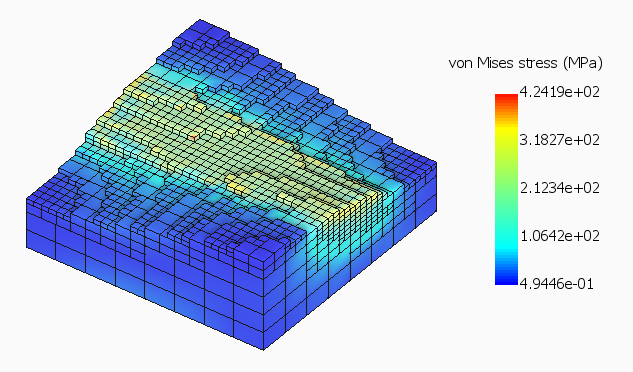

- Click , and select von Mises stress to record this stress type during simulation, then click OK.

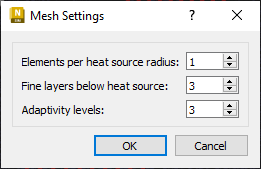

- Click

Mesh Settings, and set the values shown for

Elements per heat source radius (1),

Fine layers below heat source (3), and

Adaptivity levels (3).

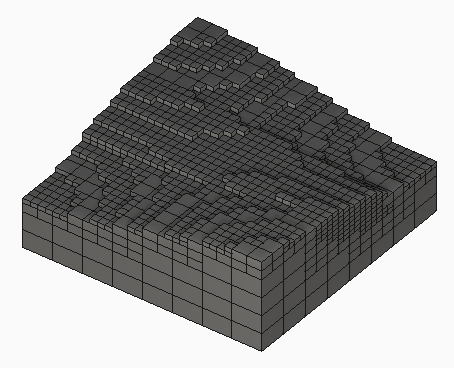

- Click

Mesh Preview. If you have not already saved the project, you will be asked to do so.

- Assured the mesh looks fine, click Solve to start the simulation. This will take about an hour to run on a 4-core computer.

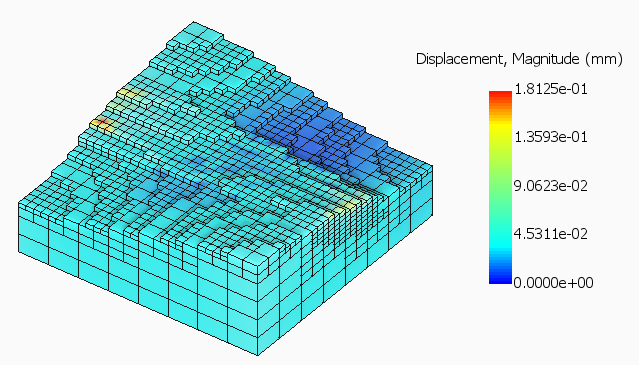

- When Results appear, examine the Displacement and von Mises stress results. Note the large number of increments in the simulation results.