Generate a PRM file from custom process parameters.

Video length (4:40).

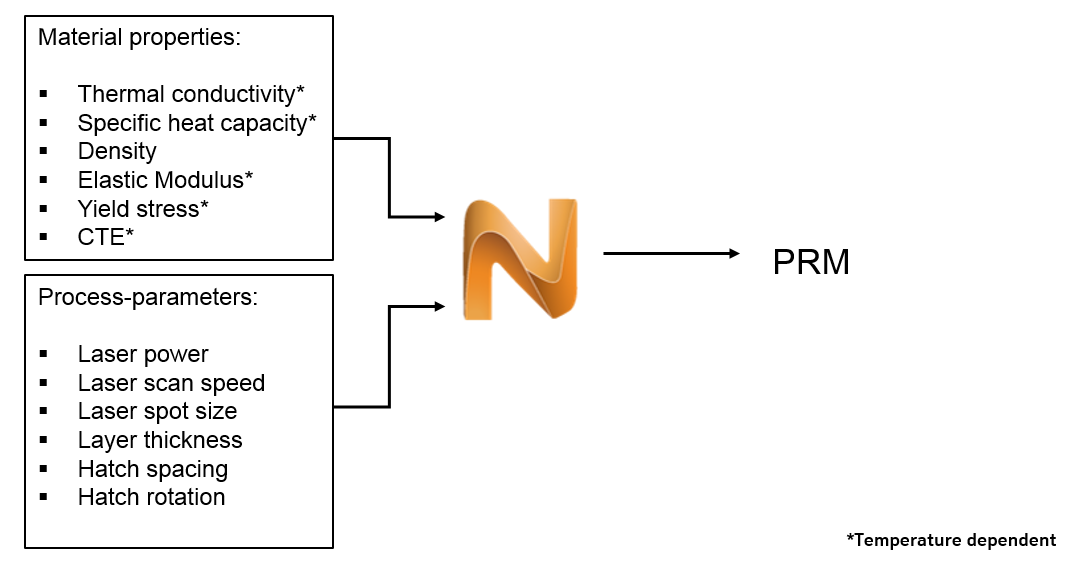

A processing parameter (PRM) file records machine process parameters and material properties. A moving heat source is applied to the material on a small-scale analysis. The PRM file stores the mechanical response of the material to the machine parameter setting. This can be extrapolated to a full part. For each new material or processing parameter set, a new PRM generation must be completed. However the resulting PRM file can be reused for any future simulation using the same combination of material and processing parameters.

Follow the step-by-step instructions shown in the video.

- In the Simulation Utility window, click

.

.

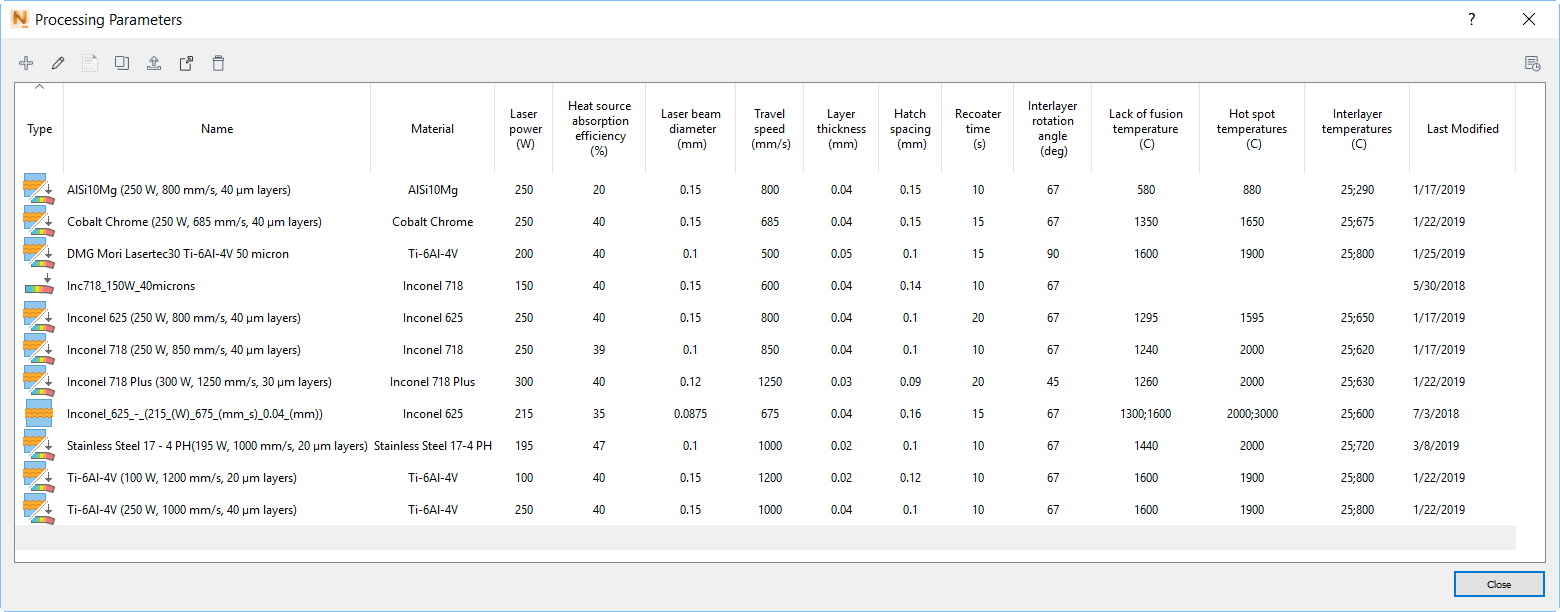

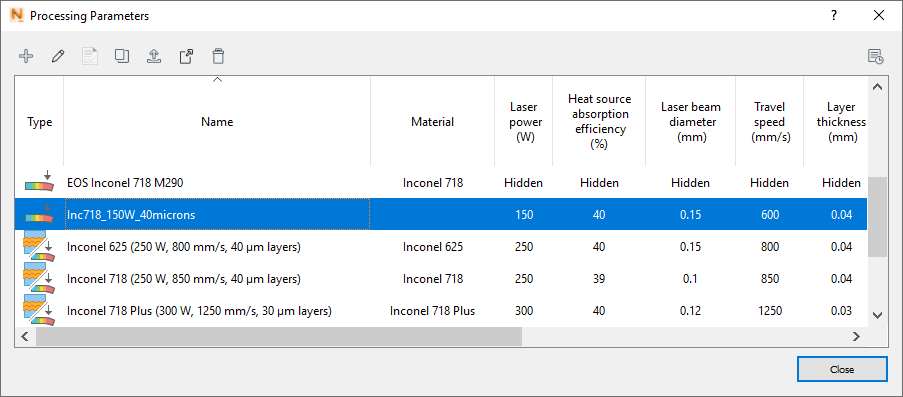

The Processing Parameters dialog box opens, showing the available library of PRM files.

This dialog supports many management functions for PRM files, using the icons along the top of the dialog, and a right-click menu from a selected file. For more information, see Processing Parameters.

- In this example, we want to simulate the creation of a new PRM file; in the upper left of the dialog, click

New

to open the

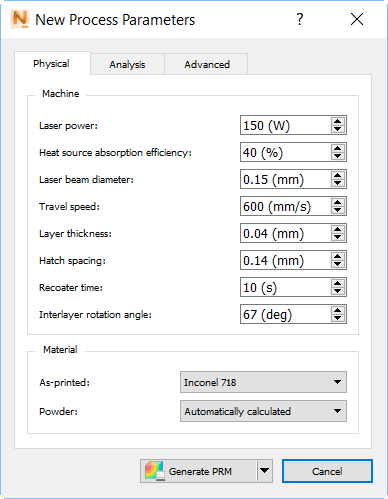

New Process Parameters dialog, which is used to set processing parameters. For this example, custom process parameters will be used.

to open the

New Process Parameters dialog, which is used to set processing parameters. For this example, custom process parameters will be used.

- Adjust the values to match the parameters shown below. You may need to change your Settings to Metric to enter values below in millimeters rather than meters. If so, see the

Netfabb Simulation Settings Help topic.

If a new material is ever required, it can be added temporarily in this dialog, using the Material > As-printed menu, or permanently by creating a new material in the Materials Library. PRM files are encoded with the material properties used to generate them. For this example, choose the Inconel 718 properties included with the software.

If you want to review settings available on the Analysis and Advanced tabs of this dialog, see New PRM File Creation.

- Click

Generate PRM.

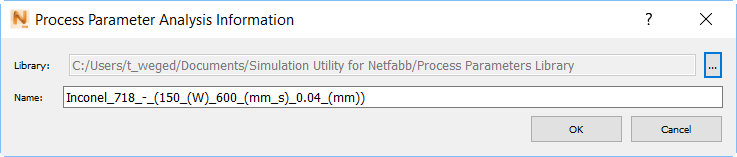

A dialog indicates a library path and name for the new PRM file. The file name can be changed here, but if you want to change the library path, go to .

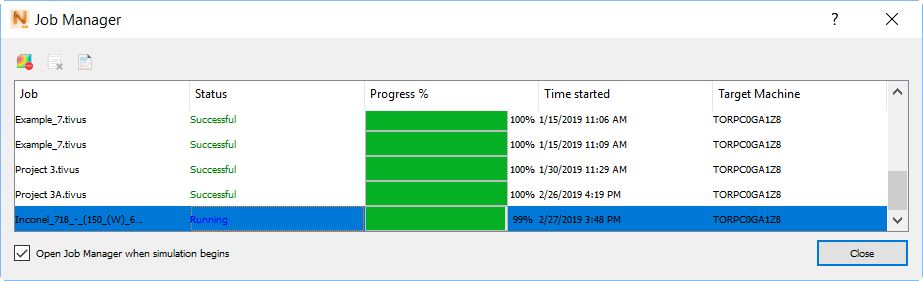

Choose a descriptive name that will identify the PRM file for future use. When the OK button is pressed, the simulation starts running, and typically the Job Manager opens to show the job progress. Because this process could take several hours to complete, you may want to cancel the solve.

- To cancel the solve in the Job Manager, select the job, and then click

Cancel

in the upper left of the dialog.

in the upper left of the dialog.

- Close the Processing Parameters dialogs.

- If you close the Job Manager, you can reopen it by clicking Job Manager

from the

Home tab,

Analysis panel.

from the

Home tab,

Analysis panel.

While a job is running, you can click the Logs

button in the upper left of the

Job Manager from time to time to see the process in action.

button in the upper left of the

Job Manager from time to time to see the process in action.

Depending on system resources, the time required to generate a PRM file can vary widely. However, this process needs to be completed only once for each combination of material and processing parameters.

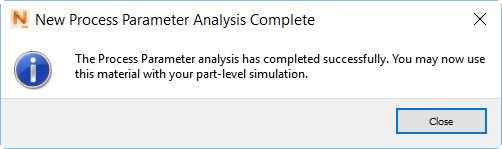

When the simulation is complete the following prompt opens:

When you click , your new PRM file appears in the library.

If you did not take the time to generate the PRM file, the package of sample files for use with the tutorials (available on the Download Page) includes a copy of the PRM file configured in this tutorial, inside the Example 2 folder. You can import it into your Processing Parameters Library folder, and it will show up with the others:

The icon for this PRM file indicates that it is designed specifically for stress and distortion analysis, whereas the other Inconel PRM files shown here are designed for a combination of stress, distortion, lack of fusion, and hotspot analysis

.

.