Click to generate a mesh preview of the active part and build plate. If the project has not already been saved, a prompt will appear to save the project before the mesh preview is begun. Performing a mesh preview is useful to ensure the mesh settings chosen create a voxel mesh that adequately captures the geometry of the part before committing to a full simulation. Mesh settings should be chosen so that the thinnest geometric feature has at least 2 elements through its thickness to ensure that the part can freely distort during simulation. Good FE practice includes performing a mesh convergence study for each geometry.

Details about mesh settings and instructions on calculating mesh convergence can be found in the Mesh Settings topics for Powder Bed Fusion and Directed Energy Deposition.

The Clipping option on the View ribbon can be useful to investigate the mesh quality after preview.

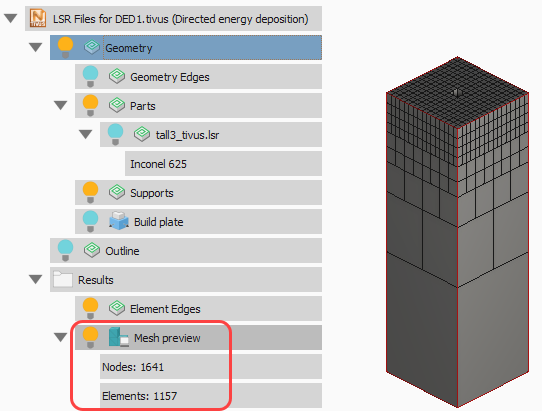

In the Browser, below the Mesh Preview icon, mesh metrics are shown for the number of Nodes and Elements, which can be used to estimate complexity of a simulation using the current mesh settings. Mesh preview for powder bed fusion models also shows Layer-Nodes (number of nodes X number of simulated layer groups).

Powder bed fusion mesh preview

DED mesh preview

Mesh Preview results for powder bed fusion models include the Structure type, which can be used to check whether the proper settings and conditions have been selected.