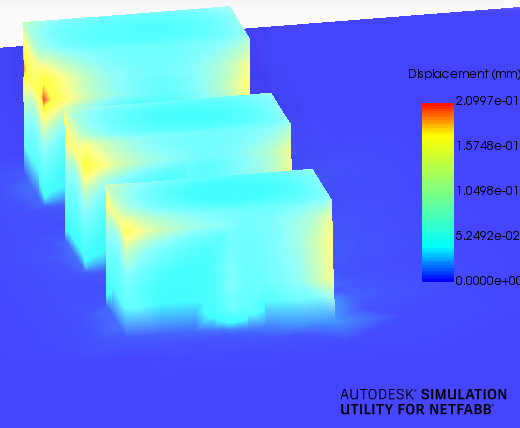

One of the biggest challenges with additive manufacturing of metal parts is reducing the number of build failures. Build failures commonly occur due to lack of support structures or recoater blade interference. Even if these challenges are overcome, warping after cooling can change a part's shape to unacceptable levels. Let's explore how Netfabb and Simulation Utility can be used together to solve this problem.

From Netfabb to Simulation Utility

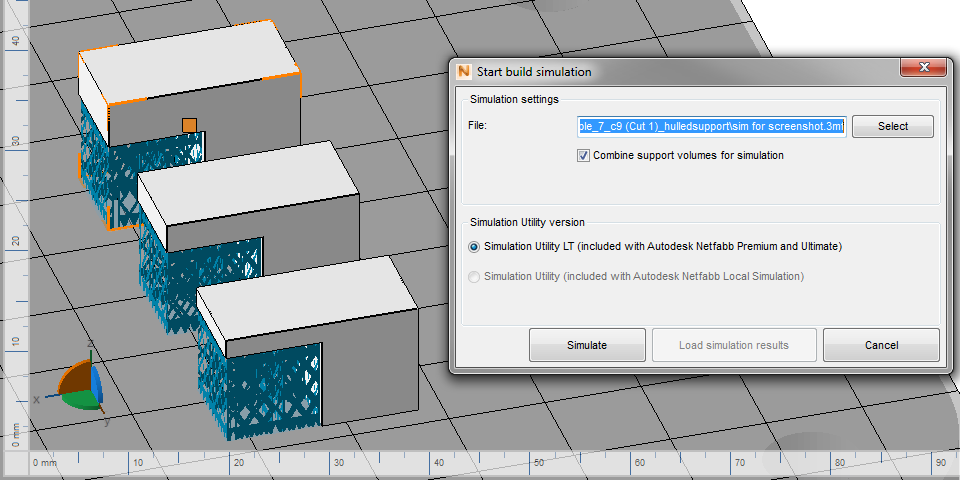

To save time in setting up a simulation, process values as defined by the current workspace settings are transferred directly from Netfabb to Simulation Utility, using the 3MF file format.

Send a prepared print job to Simulation Utility directly from the machine workspace ...

… into Simulation Utility.