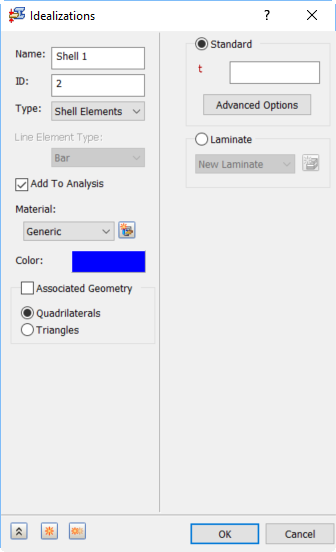

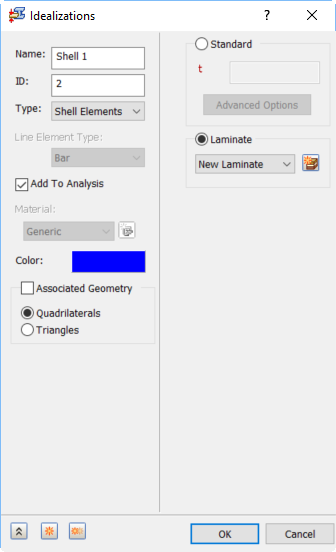

- Associated Geometry: Choose the face or faces to which you want to apply the Idealization properties. When the

Associated Geometry option is NOT activated, the Idealization is applied to the entire model (all faces). Choose one of the following two radio buttons:

- Quadrilaterals: Generate quadrilateral elements for all faces of all parts.

- Triangles: Generate triangular faces for all faces of all parts.

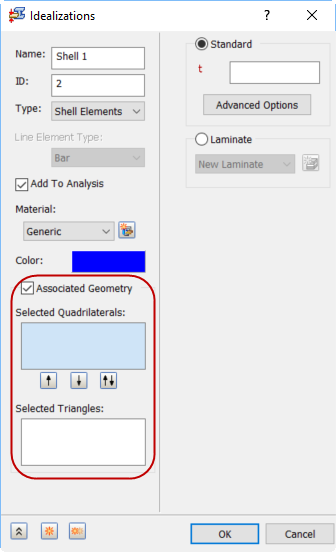

Alternatively, activate the Associated Geometry option to define unique Idealization properties for individual faces within the part or assembly.

Before selecting the faces…

- Click in the Selected Quadrilaterals box, then select the desired faces. The selected faces are listed in the Selected Quadrilaterals box, and they will be meshed with quadrilateral shell elements.

- Click in the Selected Triangles box, then select the desired faces. The selected faces are listed in the Selected Triangles box, and they will be meshed with triangular shell elements. This option is useful if you are creating a skin of shell elements on a face of a solid (tetrahedral) element part, so that the shell and solid meshes match.

- Use the vertical arrow buttons to move selected items from one list to the other, or to swap the contents of the two boxes.

There are two main options available for shell elements: Standard and Laminate.

Standard Shells

- Thickness (t): A shell element thickness that will be distributed equally on both sides of the surface.

- NSM: A non-structural mass for the shell elements will be used in the calculations.

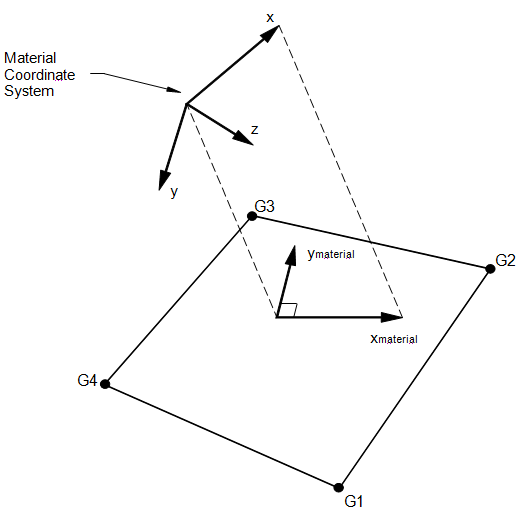

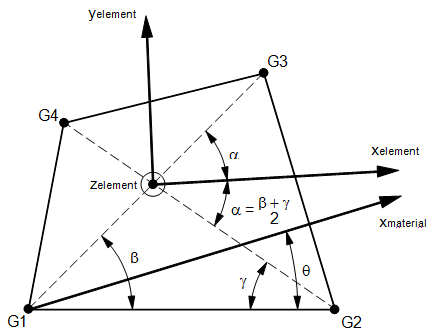

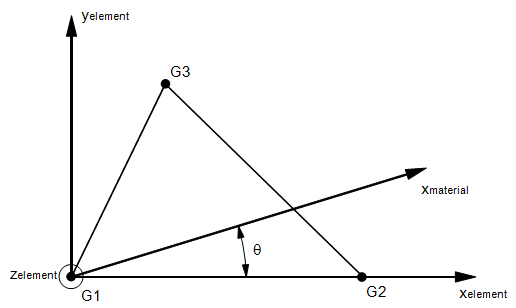

- Quadrilateral Shell Element Material Coordinate System Definition:

- Quadrilateral Shell Element Geometry and Coordinate System:

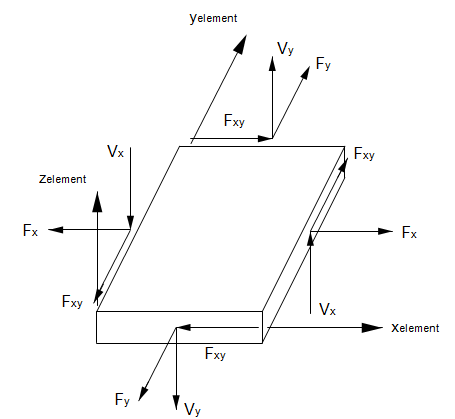

- Forces in Quadrilateral Shell Elements:

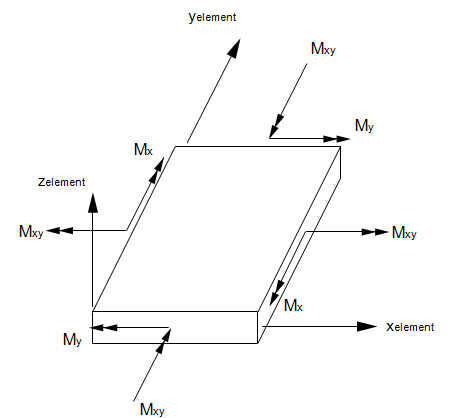

- Moments in Quadrilateral Shell Elements:

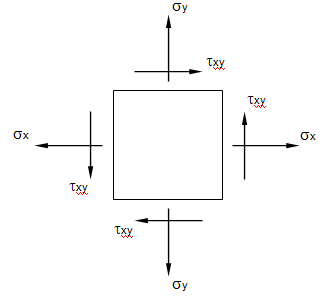

- Stresses in Quadrilateral Shell Elements:

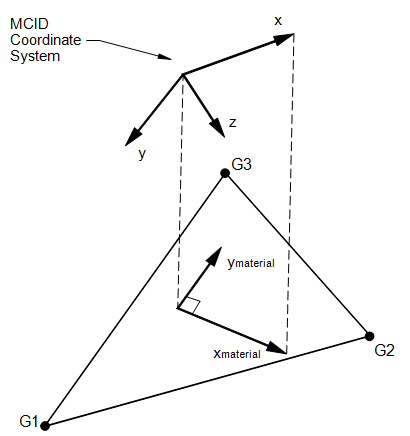

- Material Coordinate System Definition for Triangular Shell Elements:

- Element Geometry and Coordinate Systems for Triangular Shell Elements:

- Quadrilateral Shell Element Material Coordinate System Definition:

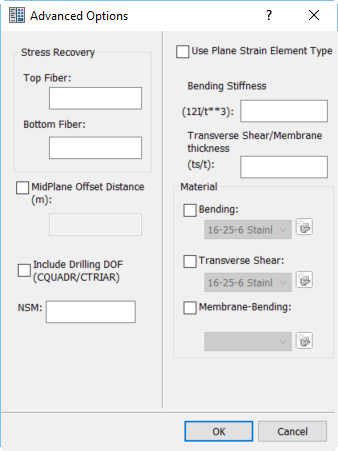

- Advanced Options: Allows you to define the following additional properties for Standard shells.

- Stress Recovery:Define top and bottom fiber distances for stress computation. It uses the right-hand rule and the order in which the grid points are listed on the connection entry to determine the positive direction.

- MidPlane Offset Distance: Define the offset distance from the surface of grid points to the element reference plane. This can be visible when display cross section is on.

- Use Plane Strain Element Type: This allows you to shift the regular shell element to Plane Strain Element. When this is checked the bending and membrane properties (like the ratio of transverse shear and membrane thickness) and respective material properties are disabled as they are not applicable.

- Include Drilling DOF (CQUADR/CTRIAR): When this option is NOT activated, the shell elements support five degrees of freedom (DOF)—three translations and rotations about two in-plane axes (flexural distortion). The rotational DOF about the normal (drilling) axis is not directly supported. However, there is some stiffness included (as controlled by the parameter K6ROT).

Activate the Include Drilling DOF (CQUADR/CTRIAR) option if you want to directly consider normal nodal rotations, or if you need to transmit moments about the axis normal to the plane of the element. Normal nodal moments produce in-plane translations of corner and midside nodes. The effect is typically more accurate when you include the drilling DOF. This option should be specified when:

- Curved shells are modeled

- Beam, bar, or rod elements are attached to the shells

- Rigid elements are used with the shells, and with all 6 degrees of freedom made dependent

You should adhere to the following guidelines when using the Include Drilling DOF (CQUADR/CTRIAR) option:

- At least one grid point in the model must have the drilling degree of freedom constrained, which is not the case for the bending degrees of freedom. The user must consider the drilling DOF when applying boundary conditions (that is, if you intend an edge to remain straight, you should constrain the drilling DOF). This also applies to edge loads.

- Do not over constrain the drilling degree of freedom (meaning, do not constrain all drilling DOF in the model).

Laminate Shells

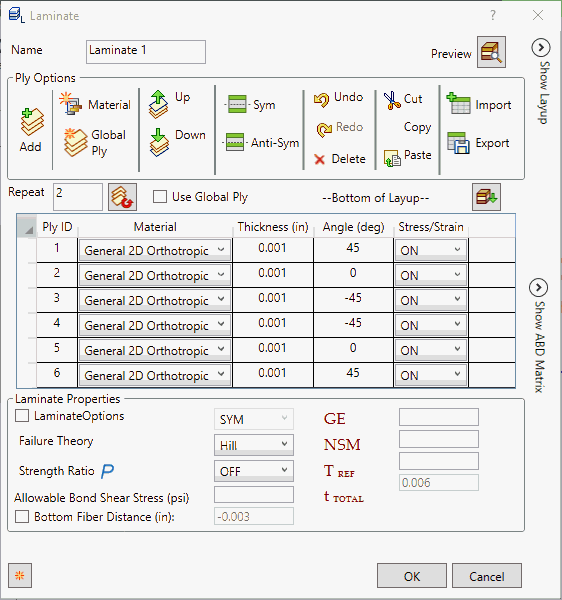

- The

Laminate option allows you to define a composite laminate property. Click on the

New Laminate button. The

Laminate Dialog opens up.

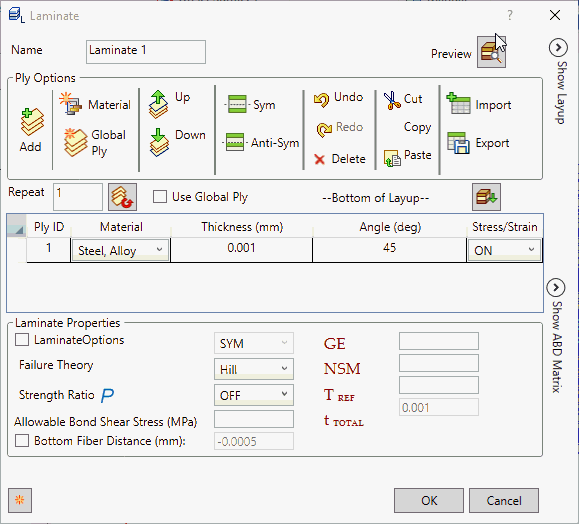

- Ply Options allow you to:

- Add: Add the ply.

- Material: Define a new material.

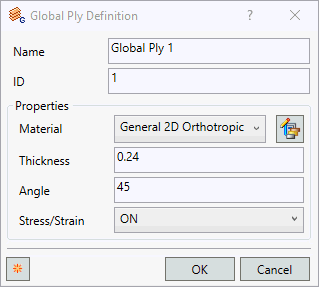

- Global Ply: Define the global ply as shown in the image below.

- Up: Move the selected ply one step above.

- Down: Move the selected ply one step below.

- Sym: Create the symmetry of the select ply/plies.

- Anti Sym: Create the anti symmetry of the select ply/plies.

- Undo: Undo the operation performed.

- Redo: Redo the operation performed.

- Delete: Delete the selected ply/plies.

- Cut: Cut the selected ply/plies.

- Copy: Copy the selected ply/plies.

- Paste: Paste the cut or copied ply/plies.

- Import: Import the ply details which is in csv format.

- Export: Export the ply details in csv format.

- Repeat: Allows you to create a multiple ply for the selected ply/plies.

- Use Global Ply: Allows you to enable the global ply column.

- Lay Up: Allows you to flip the plies from Bottom of Layup to Top of Layup. It flips the plies visually. Exporting the Nastran file always is in bottom layup format.

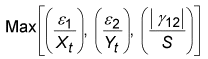

- Click

Add from the

Ply Options to start the first ply definition. This ply would be the bottom most ply in the layup.

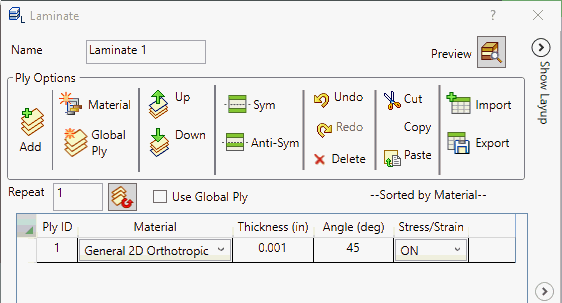

- Ply ID: Each ply (layer) of the composite has a unique ID. These ID’s are automatically generated by Inventor Nastran as they are created in this dialog box. They cannot be changed.

- Material: Each ply can have a different material. In order to select a material from this pull-down menu, it should be predefined under Materials.

- Thickness: Each ply can have its own thickness value.

- Angle: This is the ply orientation angle. This angle is measured with respect to the material orientation angle. A zero angle ply corresponds to alignment with the material orientation.

- Stress/Stain: Allows the control of stress output on each ply by setting it to ON or OFF.

-

Laminate Properties:

- Laminate Options: Allows you to define different forms of laminates like SYM, HCS, FCS, ACS, SME, or SMC.

- If LAM = SYM, only plies on one side of the element center line are specified. The plies are numbered starting with 1 for the bottom layer. If an odd number of plies is desired with LAM = SYM then the center ply thickness (Ti) should be half the actual thickness.

- If LAM = HCS, LAM = FCS, or LAM = ACS a composite sandwich is defined for the purpose of facesheet stability index output. HCS specifies a honeycomb core material, FCS specifies a form core material, and ACS selects either HCS or FCS based on the core material specified.

- If LAM = SME, the ply effects are smeared and the stacking sequence is ignored. If LAM = SMC, a composite sandwich is defined using equivalent orthotropic properties.

- Failure Theory: Ply failure theory. The following theories are allowed. If blank, then no failure calculation is preformed.

Hill is set as the default failure theory.

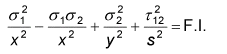

- HILL for the Hill theory.

Orthotropic materials with equal strengths in tension and compression.

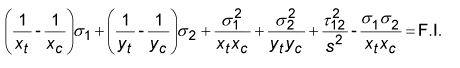

- HOFF for the Hoffman theory.

Orthotropic materials under a general state of plane stress with unequal tensile and compressive strengths.

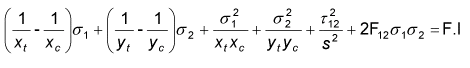

- TSAI for the Tsai-Wu theory.

Orthrotropic materials under a general state of plane stress with unequal tensile and compressive strengths.

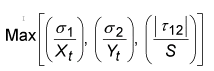

- Max Stress for the maximum stress theory.

- Max Strain for the maximum strain theory.

- LARC02 for NASA LaRC theory.

Orthotropic materials comprised of unidirectional plies under a general stare of plane stress. For more details see the Autodesk Nastran User's Manual, Reference 5.

- PUCK for the Puck PCP theory.

Orthotropic materials comprised of unidirectional plies under a general stare of plane stress. For more details see the Autodesk Nastran User's Manual, Reference 12 and 13.

- MCT for the Multicontinuum theory.

Orthotropic materials comprised of unidirectional plies or plain weave fabric under a general stare of plane stress. For more details see the Autodesk Nastran User's Manual, Reference 20, 21 and 22.

- HILL for the Hill theory.

- Strength Ratio: It controls the output of Tsai Strength Ratio, which is provided in place of Failure Index for composite element ply results output. When it is set ON, it allows to define Parameter PARAM,STRENGTHRATIO,ON, and the Tsai Strength Ratio is calculated. Strength Ratio is considered more useful than Failure Index because it indicates exactly how to change applied loading to achieve optimal ply performance.

- Allowable Bond Shear Stress: This value defines the interlaminar shear stress of a Bond Material. This value is required to get Bond Failure Index output.

- Bottom Fiber Distance: Represents half of the total thickness by default. It can be changed by checking the box on the left and typing in a new value in the box to its right.

- GE (Damping Coeff.): This value defines the structural element damping coefficient, which is twice the critical damping ratio

to be used in dynamic analyses. Planned to be supported in later versions.

to be used in dynamic analyses. Planned to be supported in later versions.

- NSM: It allows you to define nonstructural mass per unit area.

(Ref. Temperature):

This value defines the reference temperature of the composite plies (all plies) to be used for temperature dependent material properties. This feature will be supported in later versions.

(Ref. Temperature):

This value defines the reference temperature of the composite plies (all plies) to be used for temperature dependent material properties. This feature will be supported in later versions.

(Total Thickness): It shows the total thickness specified in the laminate.

(Total Thickness): It shows the total thickness specified in the laminate.

- Laminate Options: Allows you to define different forms of laminates like SYM, HCS, FCS, ACS, SME, or SMC.

- Ply Options allow you to:

-

Ply Creation Techniques:

- There are many convenient ways of defining the different ply properties.

- For the first row, click Add, click in the Material column of the row and select a material. The default values for the rest of the columns are loaded automatically.

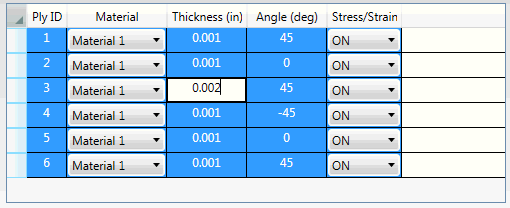

- Now select the Ply ID

1.

- With a

2 in the box beside the repeat button (1 is default), click the

Repeat button. The first row is copied two times. The following figure illustrates the result.

- Change the angles to 45, 0, and -45 from top to bottom.

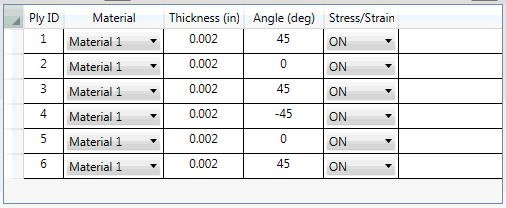

- Now select all the Plies. Then click the Symmetric button.

- This will produce mirrored rows of the selected plies.

- The following figure illustrates the result.

- Similarly, Anti-Symmetric would produce mirrored rows but with opposite signs for the ply angles.

- You can select multiple

Plies, and then right-click on a field to change. Then select

Edit.

- Change the respective property of any ply. All the corresponding properties are changed at once.

-

Laminate Dialog Example:

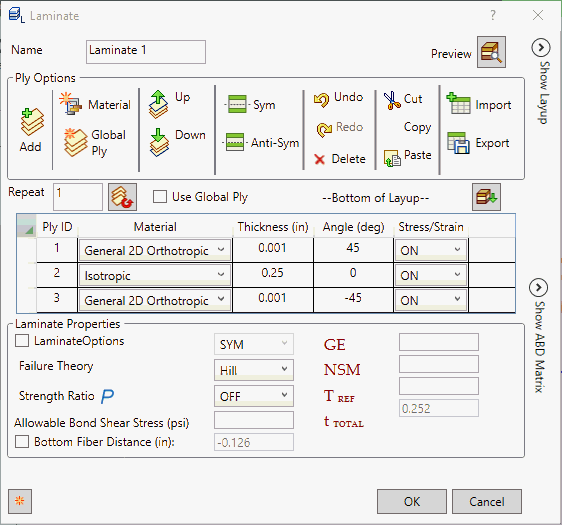

- The lay up configuration in this example has three plies:

- In order to define the configuration of a 3-ply composite plane property, the Laminate Dialog entries would look as shown below. Note that the property is defined from the bottom up.

- Notice that the Bottom Fiber Distance is updated automatically (-1/2 total thickness). It is the distance from the reference plane to the bottom surface. Ply 1 is the bottom ply and the last ply defined is the top ply (ply 3 in this case).

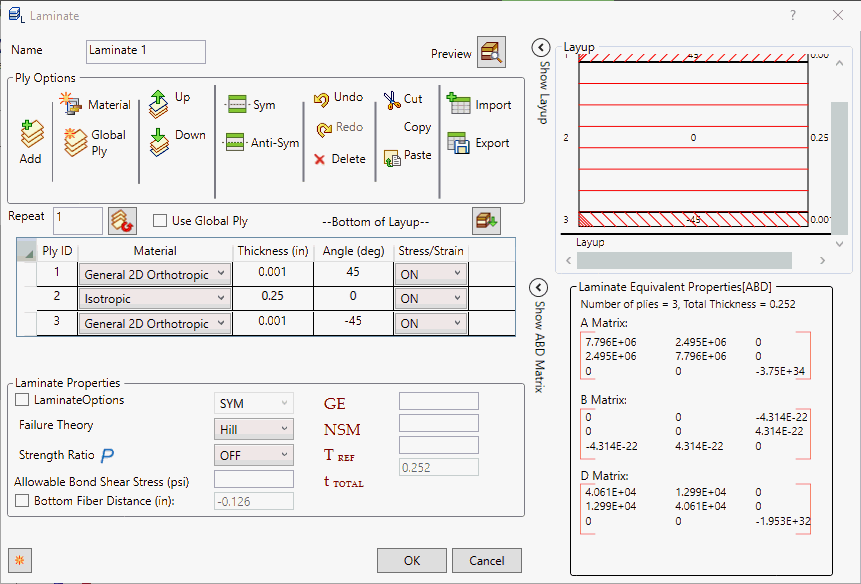

- Click on

Preview button

to view the

Show Layup and

Show ABD Matrix.

to view the

Show Layup and

Show ABD Matrix.

- Show Layup and Show ABD Matrix will individually expand when

is clicked. In order to collapse, click the

is clicked. In order to collapse, click the

button.

button.

- Show Layup: It represents the graphical representation of the plies defined by showing.

- Show ABD Matrix: Laminate equivalent properties are displayed in ABD matrix with number of plies and total thickness defined in the ply.

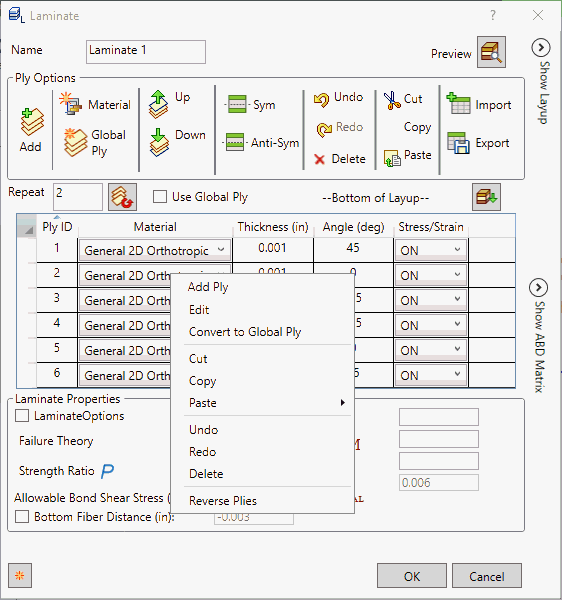

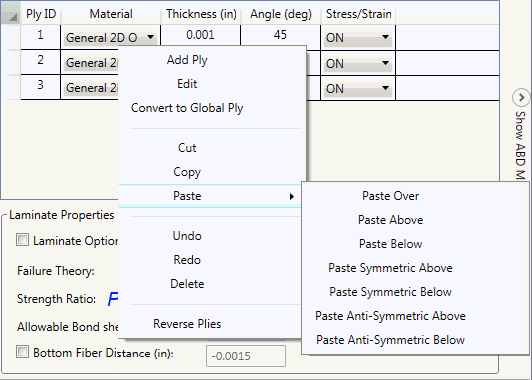

- Popup Menu: When we right-click on the rows, the popup menu is shown as below:

- Add Ply: Add new ply.

- Edit: Edit the property. Select any property say material, globalply, thickness etc. Multiply selection with edit feature is used to change the value in all plies.

- Convert to Global Ply: It allows to convert normal ply to global ply definition.

- Cut: Cut the selected ply/plies.

- Copy: Copy the selected ply/plies.

- Paste: Paste the cut or copied ply/plies. It has different options paste over, paste above, paste below, paste symmetric above, paste symmetric below, paste anti-symmetric above and paste anti-symmetric below.

- Undo: Undo the operation performed.

- Redo: Redo the operation performed.

- Delete: Delete the selected ply/plies.

- Reverse Plies: Reverse the selected ply/plies.

- The lay up configuration in this example has three plies: