Nitinol material is used only in Nonlinear analysis. After selecting Nitinol from the Type drop-down, the following material sections will become available: General, Structural and Nitinol.

-

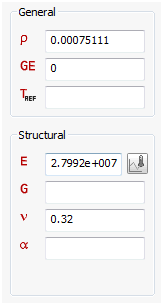

General and Structural

- You can input Young’s modulus, shear modulus, Poisson’s ratio, thermal expansion coefficient, mass density under the General and Structural section.

-

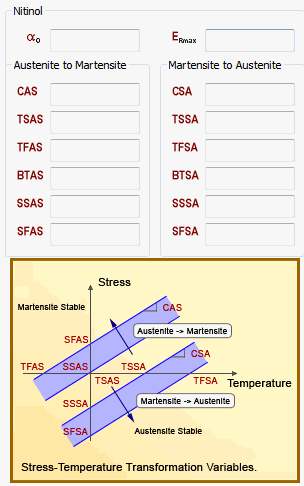

Nitinol

- This material property is used for shape memory alloys.

- It needs pressure coefficient

and maximum residual strain

and maximum residual strain  .

. - The transformation stresses and temperature can be combined such that the transformation stress can be calculated by using the data specified for autensite to martensite and vice versa.

- Starting stress for transformation from austensite to martensite is SSAS -CAS*TSAS.

- Ending stress for transformation from austensite to martensite is SFAS -CAS*TFAS.

- Starting stress for transformation from martensite to austensite is SSSA -CSA*TSSA.

- Ending stress for transformation from martensite to austensite is SFSA -CSA*TFSA.

- Temperatures should satisfied relation:

TFAS<TSAS<TSSA<TFSA

- When BTAS and BTSA are zero, the material model is linear. When BTAS and BTSA are non-zero, the material model is exponential with BTAS and BTSA as coefficients.