Viscoelastic material is used only in Nonlinear analysis. After selecting Viscoelastic from the Type drop-down, the following material sections will become available: General, Structural, Viscoelastic and Experimental Data Function.

-

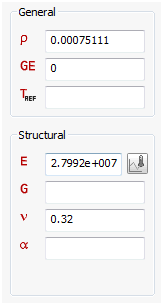

General and Structural

- You can input Young’s modulus, shear modulus, Poisson’s ratio, thermal expansion coefficient, mass density under the General and Structural section.

-

Viscoelastic

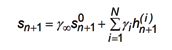

- The viscoelasticity uses the Generalized Maxwell Model. The deviatoric stress is given by:

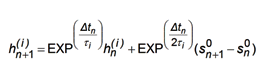

where the stress at each relaxation component is calculated by:

and

and

and  are deviatoric stresses without relaxation.

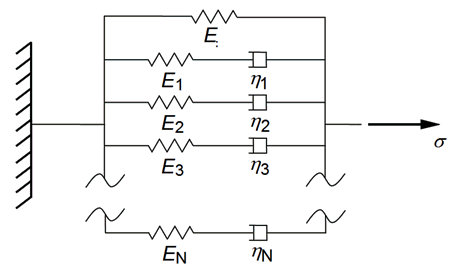

are deviatoric stresses without relaxation. - The viscoelastic relaxation occurs in the shear and/or bulk modulus. The modulus E in the following figure should be interpreted either shear modulus G or bulk modulus K.

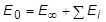

where

= stiffness at an infinite time

= stiffness at an infinite time  = stiffness at the initial time

= stiffness at the initial time

where

where

where

The

and

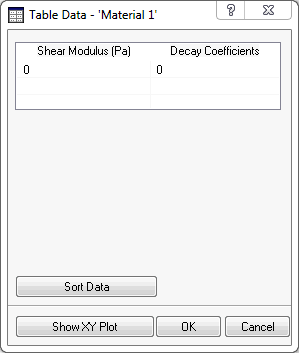

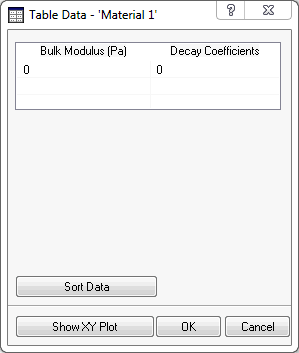

and  terms are defined using the TABVE Bulk Data entry where

terms are defined using the TABVE Bulk Data entry where  .

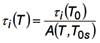

. - Viscoelastic material properties strongly depend on temperature. Instead of estimating material properties at different temperatures, an assumption called thermorheological simplicity is used in which the relaxation curve at high temperature is identical to that at low temperature when the time is properly scaled. The relaxation times in the Prony series are scaled by the following equation:

where two different scaling functions are supported.

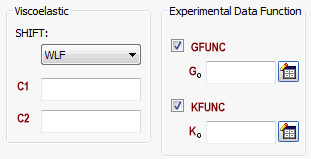

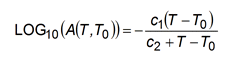

William-Landel-Ferry:

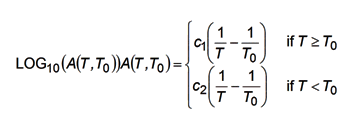

Arrhenius:

Hence, the constants C1 and C2 are defined based on the SHIFT, scaling functions selection.

- The viscoelasticity uses the Generalized Maxwell Model. The deviatoric stress is given by:

-

Experimental Data Function

- It is allowed to define the scaling functions for different modulus i.e. shear/bulk modulus relaxation function vs decay coefficients.

- G0 and K0 are the 0-th term of the shear or bulk modulus representation respectively.

- If GFUNC and KFUNC are not defined then E, G and NU values will be used to define defaults.