Parameters for Nonlinear Transient Analysis

Description: Defines a set of parameters for nonlinear transient analysis.

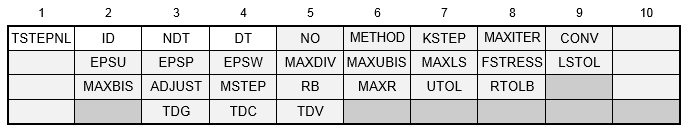

Format:

Example:

| Field | Definition | Type | Default |

|---|---|---|---|

| ID | Identification number. | Integer > 0 | Required |

| NDT | Number of time steps of value DT. See Remark 2. | Integer > 0 | Required |

| DT | Time increment. See Remark 2. | Real > 0.0 | Required |

| NO | Time step interval for output. Every NOi-th step will be output. See Remark 3. | Integer > 0 | 1 |

| METHOD | Method for controlling stiffness updates, one of the following character variables: AUTO, TSTEP, or ADAPT. See Remark 4. | Character | ADAPT |

| KSTEP | Number of time steps before stiffness update for the TSTEP method. See Remark 4. | Integer > 0 | 5 |

| MAXITER | Limit on number of iterations for each time step. See Remark 5. | Integer > 0 or AUTO | AUTO |

| CONV | Convergence criteria, one of the following character variables: U, P, or W, or any combination. See Remark 6. | Character | PW |

| EPSU | Error tolerance for displacement (U) criterion. | Real > 0.0 | See Remark 17 |

| EPSP | Error tolerance for load (P) criterion. | Real > 0.0 | See Remark 17 |

| EPSW | Error tolerance for work (W) criterion. | Real > 0.0 | See Remark 17 |

| MAXDIV | Limit on probable divergence conditions per iteration before the solution is assumed to diverge. See Remark 7. | Integer > 0 | 3 |

| MAXUBIS | Maximum number of iterations for an upward load increment adjustment. Applicable when the load increment is bisected. | Integer > 0 | 7 |

| MAXLS | Maximum number of line searches for each iteration. See Remark 8. | Integer ≥ 0 | 4 |

| FSTRESS | Fraction of effective stress ( ) used to limit the subincrement size in nonlinear material routines. See Remark 9. ) used to limit the subincrement size in nonlinear material routines. See Remark 9.

|

0.0 < Real < 1.0 | 0.2 |

| LSTOL | Line search tolerance. See Remark 8. | 0.01 < Real ≤ 0.9 | 0.5 |

| MAXBIS | Maximum number of bisections allowed for each time step. See Remark 10. | Integer > 0 | 5 |

| ADJUST | Time step skip factor for automatic time step adjustment. See Remark 11. | Integer ≥ 0 | 5 |

| MSTEP | Number of steps to obtain the dominant period response. See Remark 12. | 10 ≤ Integer ≤ 200 | Variable between 20 and 40 |

| RB | Bounds for maintaining the same time step for the stepping function. See Remark 12. | 0.1 ≤ Real ≤ 1.0 | 0.75 |

| MAXR | Maximum ratio for the adjusted incremental time relative to DT allowed for time step adjustment. See Remark 13. | 1.0 ≤ Real ≤ 32.0 | 16.0 |

| UTOL | Tolerance on displacement or temperature increment below which a special provision is made for numerical stability. See Remark 14. | 0.001 < Real ≤ 1.0 | 0.1 |

| RTOLB | Maximum value of incremental rotation (in degrees) allowed per iteration to activate bisection. See Remark 15. | Real > 2.0 | 20.0 |

| TDG | Terminate on displacement grid point identification number. See Remark 16. | Integer > 0 | |

| TDC | Terminate on displacement component number. See Remark 16. | 0 ≤ Integer ≤ 6 or MAXT or MAXR | MAXT |

| MAXT Resultant of translation displacement components. MAXR Resultant of rotational displacement components. | |||

| TDV | Terminate on displacement value. See Remark 16. | Real |

Remarks:

- The TSTEPNL Bulk Data entry must be selected by the Case Control command TSTEPNL = ID. Each solution subcase requires a TSTEPNL command and either applied loads via TLOADi data or initial values from a previous subcase. Multiple subcases are assumed to occur sequentially in time with the initial values of time and displacement conditions of each subcase. Initial conditions specified using the IC Case Control command apply only to the first subcase.

- NDT is used to define the total duration for analysis, which is NDT*DT. Since the adaptive time integration method uses a variable time increment, the actual number of time steps will usually not be equal to NDT. Also, DT is used only as an initial value for the time increment.

- Results output is generated at time steps 1, NO, 2*NO, 3*NO,…, and the last converged step. The Case Control command OTIME may also be used to control the output times.

- The stiffness update strategy is selected in the METHOD field.

- If the AUTO option is specified, the stiffness matrix is automatically updated based on convergence.

- If the TSTEP option is selected, the stiffness matrix is updated at every KSTEP increment of time.

- If the ADAPT option is selected, the time step is automatically adjusted based on the severity of the nonlinearity and a stiffness matrix update is performed.

In all methods the stiffness matrix is always updated for new subcase.

- The number of iterations for a time increment is limited to MAXITER. If the solution does not converge in MAXITER iterations, one of two actions is taken depending on the BISECT model parameter. If the BISECT model parameter is set to ON, the time increment is bisected and the analysis is repeated. If the time increment cannot be bisected (i.e. MAXBIS is attained), execution terminates with a fatal error. If the BISECT model parameter is set to OFF, the analysis is continued to the next load increment. (See Section 5, Parameters, for more information on BISECT.) The default AUTO setting uses an initial MAXITER value of 40 and automatically increases this value if the solution appears near convergence.

- The symbols (U for displacement error, P for load equilibrium error, and W for work error) and the tolerances (EPSU, EPSP, and EPSW) define the convergence criteria. All the requested criteria (combination of U, P, and/or W) are satisfied upon convergence.

- MAXDIV provides control over diverging solutions. Depending on the rate of divergence, the number of diverging solutions (NDIV) is incremented by 1 or 2. The solution is assumed to diverge when NDIV ≥ MAXDIV. If the solution diverges and the load increment cannot be further bisected (i.e., MAXBIS is attained), execution terminates with a fatal error.

- The line search is performed as required if MAXLS > 0. The line search procedure scales the displacement increment to minimize the energy error. The procedure is skipped if the absolute value of the relative energy error is less than the value specified by LSTOL.

- The number of subincrements in the material routines is determined so that the subincrement size is approximately FSTRESS * (equivalent stress).

- The number of bisections for a load increment is limited to MAXBIS. If the solution diverges, the stiffness is updated on the first divergence and the load is bisected on the second divergence.

- ADJUST controls the automatic time stepping for METHOD = ADAPT. Since the automatic time step adjustment is based on the mode of response and not on the loading pattern, it may be necessary to limit the adjustable step size when the period of the forcing function is much shorter than the period of dominant response frequency of the structure. The ADJUST option should be suppressed for the duration of short pulse loading. If unsure, start with a value for DT that is much smaller than the pulse duration in order to properly represent the loading pattern.

- If ADJUST = 0, then the automatic adjustment is deactivated. This is recommended when the loading consists of short duration pulses.

- If ADJUST > 0, the time increment is continually adjusted for the first few steps until a good value is obtained. After this initial adjustment, the time increment is adjusted every ADJUST time step only.

- If ADJUST is one order greater than NDT, then automatic adjustment is deactivated after the initial adjustment.

- MSTEP and RB are used to adjust the time increment during analysis for METHOD = ADAPT. The recommended value of MSTEP for nearly linear problems is 20. A larger value (e.g., 40) is required for highly nonlinear problems. By default, the program automatically computes the value of MSTEP based on changes in the global stiffness matrix.

The time increment adjustment is based on the number of time steps desired to capture the dominant frequency response accurately. The time increment is adjusted as follows:

where,

and,

for r < 0.5*RB

for r < 0.5*RB

for 0.5*RB ≤ r < RB

for 0.5*RB ≤ r < RB

for RB ≤ r < 2.0

for RB ≤ r < 2.0

for 2.0 ≤ r < 3.0/RB

for 2.0 ≤ r < 3.0/RB

for r ≥ 3.0/RB

for r ≥ 3.0/RB

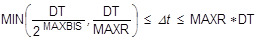

- MAXR is used to define the upper and lower bounds for adjusted time step size such that

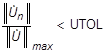

- UTOL is a tolerance used to filter undesirable time step adjustments such that

Under this condition, no time step adjustment is performed.

- The load increment is bisected if the incremental rotation for any degree of freedom

exceeds the value specified by RTOLB. This bisection strategy is based on the incremental rotation and controlled by MAXBIS.

exceeds the value specified by RTOLB. This bisection strategy is based on the incremental rotation and controlled by MAXBIS.

- When TDG, TDC, and TDV are specified the solution will proceed until either all load is applied or the specified displacement value (TDV) at grid point TDG in direction TDC is reached or exceeded. Displacements are in the displacement coordinate system of the TDG grid point.

- Default tolerance sets are determined based on solution type, nonlinear behavior requested, and desired accuracy. Accuracy is under user control and can be specified using PARAM, NLTOL (see Section 5,

Parameters, for more information on

NLTOL). The NLTOL values are only used if one or more of the EPSU, EPSP and EPSW fields on the TSTEPNL entry are blank. The following tables show the tolerance values used depending on the NLTOL model parameter setting specified.

-

Nonlinear Transient Dynamic Analysis without Contact and Material Nonlinearity

NLTOL Level of Accuracy EPSU EPSP EPSW 0 Very High 1.0E-3 1.0E-3 1.0E-6 1 High 1.0E-3 1.0E-3 1.0E-5 2 Engineering 5.0E-3 5.0E-3 1.0E-5 3 Preliminary Design 1.0E-2 1.0E-2 1.0E-4 Default Engineering 5.0E-3 5.0E-3 1.0E-5 -

Nonlinear Transient Dynamic Analysis without with Material Nonlinearity

NLTOL Level of Accuracy EPSU EPSP EPSW 0 Very High 1.0E-4 1.0E-4 1.0E-8 1 High 5.0E-4 5.0E-4 1.0E-8 2 Engineering 5.0E-4 5.0E-4 1.0E-7 3 Preliminary Design 1.0E-3 1.0E-3 1.0E-6 Default Engineering 5.0E-4 5.0E-4 1.0E-7 -

Nonlinear Transient Dynamic Analysis with Contact

NLTOL Level of Accuracy EPSU EPSP EPSW 0 Very High 1.0E-3 1.0E-3 1.0E-6 1 High 1.0E-3 1.0E-3 1.0E-5 2 Engineering 5.0E-3 5.0E-3 1.0E-5 3 Preliminary Design 1.0E-2 1.0E-2 1.0E-4 Default Engineering 5.0E-3 5.0E-3 1.0E-5 -

Nonlinear Transient Heat Transfer

NLTOL Level of Accuracy EPSU EPSP EPSW 0 Very High 1.0E-3 1.0E-3 1.0E-6 1 High 1.0E-3 1.0E-3 1.0E-6 2 Engineering 1.0E-3 1.0E-3 1.0E-6 3 Preliminary Design 1.0E-3 1.0E-3 1.0E-6 Default Engineering 1.0E-3 1.0E-3 1.0E-6

-