Use the Feature external thread milling page to create an external thread.

Depth type — Select how to determine the maximum thread depth.

- Feature — The thread starts at the base of the boss. This disables the Depth field as PowerMill calculates this value.

- User defined — The thread starts at a distance below the top of the boss. Enter this distance in the Depth field.

Depth — Enter the maximum thread depth. This option is only available if you select a Depth type of User defined. If you select a Depth type of Feature, PowerMill calculates this values for you.

Clearance — Enter the distance above the top of the boss. By default, this is the same as the Incremental start Z.

Turns — Enter the number of turns of the thread milling tool. Tall bosses may need more than one turn.

Pitch — Enter the distance from one thread groove to the next.

Tolerance — Enter a tolerance value to determine how accurately the toolpath follows the boss.

Number of start positions — Enter a value to create identical toolpaths that are rotated about the tool axis and spaced equidistantly. This enables you to generate intertwined threads.

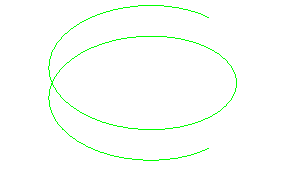

Toolpath with one start position:

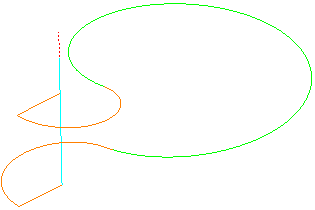

Toolpath with three start positions:

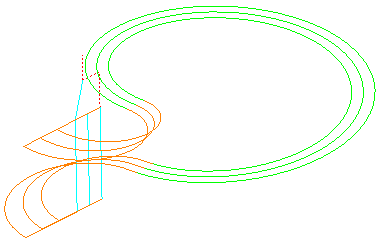

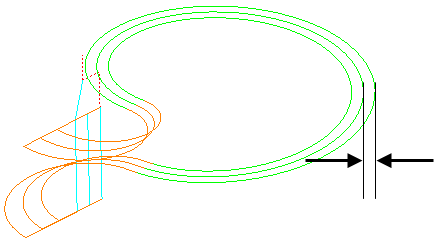

Radial passes— Enter the number of radially spaced helical toolpaths:

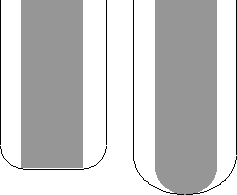

One pass:

Three passes:

Stepover — Enter the distance between successive passes.

Cut Direction — Select the milling technology. The combination of Cut Direction and Handedness determines the cut direction.

|

Right hand thread |

Left hand thread |

|

|

Climb |

Clockwise, downwards |

Clockwise, upwards |

|

Conventional |

Counter-clockwise, upwards |

Counter-clockwise, downwards |

Handedness — Select the rotational direction of the thread as it moves in the positive Z direction.

- Left — Creates a helical toolpath that rotates clockwise in the positive Z direction.

- Right — Creates a helical toolpath that rotates counter-clockwise in the positive Z direction.

Thickness — Enter the amount of material to be left on the part. Click the

Thickness

button to separate the

Thickness

box in to

Radial thickness

button to separate the

Thickness

box in to

Radial thickness

Axial thickness

Axial thickness

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

. Use these to specify separate

Radial and

Axial thickness as independent values. Separate

Radial and

Axial thickness values are useful for orthogonal parts. You can use independent thickness on sloping walled parts, although it is more difficult to predict the results.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Radial thickness — Enter the radial offset to the tool. When 2.5-axis or 3-axis machining, a positive value leaves material on vertical walls.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.

Axial thickness — Enter the offset to the tool, in the tool axis direction only. When 2.5-axis or 3-axis machining, a positive value leaves material on horizontal faces.