Periodic Boundary Conditions

Periodic boundary conditions (cyclic symmetry) allow modelling of a single passage of an axial or centrifugal turbomachine. It is not a sliding mesh implementation (like the full rotating device), but will capture the flow within the blade passage. Periodic boundary conditions can also be used to simulate non-rotating devices such as a single blade passage through a stator cascade.

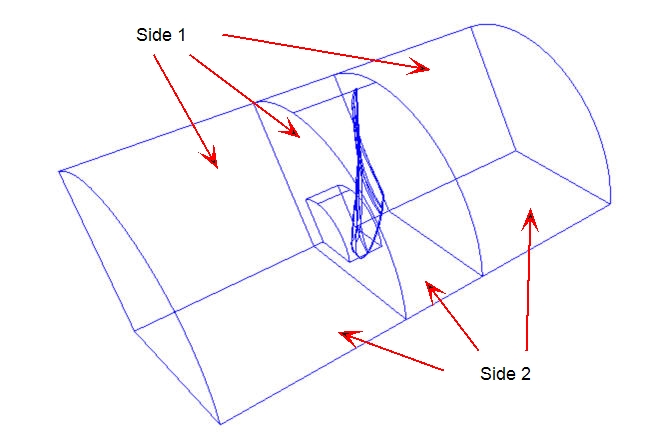

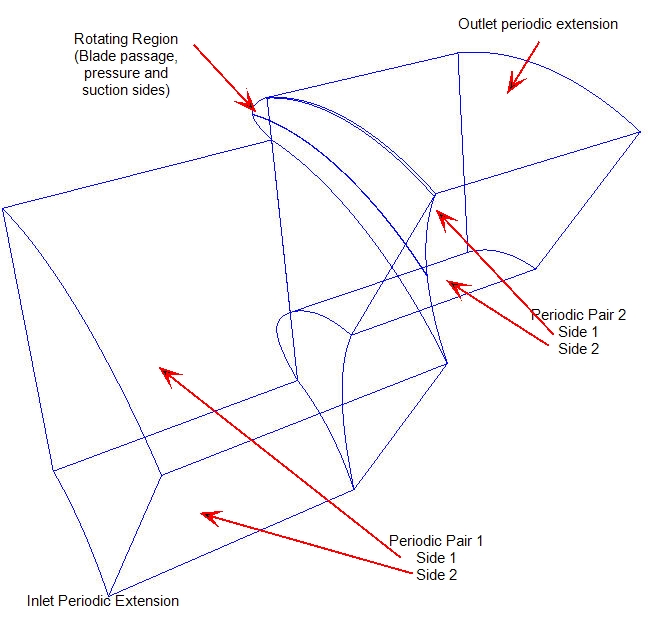

For such an analysis, only a single blade passage is modeled. Additional volumes are added to the inlet and the outlet of the model. These should be distinct volumes from the blade passage as they do not rotate. Periodic boundary conditions are always applied in pairs, typically to surfaces on the inlet and outlet extensions that are not walls or openings.

Note that models containing periodic boundary conditions cannot be remeshed and continued from a saved iteration. If the mesh is changed, the model must be started from the beginning (iteration 0). This is due to the nodal reorganization that occurs at the onset of analyses containing periodic boundary conditions.

Boundary Conditions

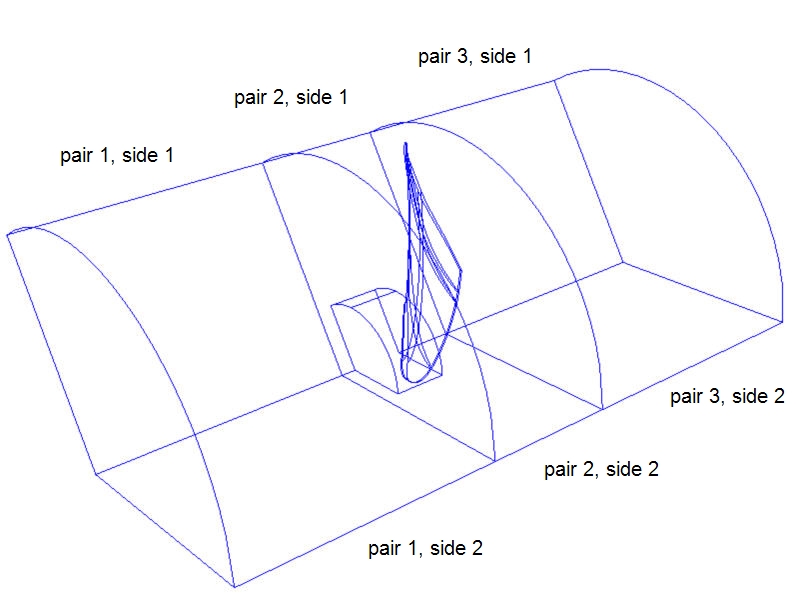

The sides of the extensions must be translated or offset from each other in the same manner. For example, if the sides of the inlet extension are rotated 30 degrees from each other, then the sides of the outlet extension must be rotated 30 degrees from each other as well. Alternatively, if the periodic sides of the inlet extension are translated in the Y direction 3 inches, then the periodic sides of the outlet must be translated 3 inches in the Y direction as well.

At least one set of periodic surfaces in the model must be planar. As long as one set is planar, the other surfaces can be curvilinear.

In 2D models, edges in a periodic pair must be within three degrees of each other, and must be the same length. Additionally, all normals from one surface must pierce the other, and vice versa.

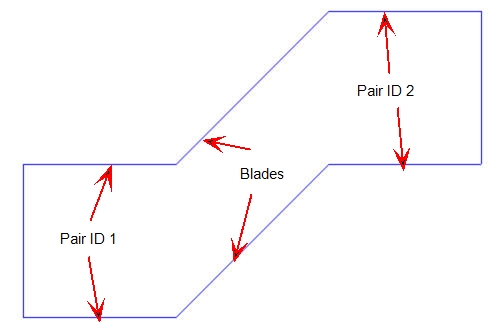

When applying a periodic condition, a pair ID is required. Use an integer value for the pair ID, and use the same value on the periodic surfaces of each extension. Additionally, a unique side ID is required for each member of a pair. For example, one surface of a periodic pair might have pair ID =1 and side ID =1. The corresponding surface in the pair would have pair ID =1, and side ID = 2.

The side ID should be consistent from one region to the next. This is shown:

Being consistent with the sides from one region to the next will greatly speed-up startup processing. If side IDs are not marked consistently, the start-up processing of the analysis will take considerably longer.

Geometry Configuration

There are two ways to configure the rotating region based on the blade passage. One approach is for the passage to be exactly between the blades (extending from the suction side of one blade to the pressure side of the other):

This approach is better for most centrifugal devices and axial devices that have a large number of blades or high degree of blade curvature.

Alternatively, the rotating region can extend from the mid-point of one passage to the mid-point of the neighboring passage. In this case, a single blade will run through the middle of the rotating region. The blade should either be a cutout or should be a solid:

Turbomachinery analyses using periodic conditions are only useful for blade passages. Such analyses are not appropriate for geometries in which a non-moving solid is included, such as a centrifugal pump surrounded by a volute.

The blade passage will be set up as a rotating region, and the rotational speed and direction of rotation must be defined. Periodic boundary conditions are required on the sides of the rotating region as well, if the blade is centered within the region. If the sides of the rotating region are the pressure and suction sides of the blade, then it is not necessary to assign periodic conditions to the sides of the rotating region.

Periodic boundary conditions can also be used for non-rotating devices, such as a stator cascade. Periodic pairs are required at the inlet and outlet extensions:

Analyses with periodic boundary conditions that include a rotating region must be run transient. For analyses of non-rotating devices, it is not required to run as a transient analysis.

Note that periodic boundary conditions are included in the Basic configuration, but the Motion Module is required to analyze rotating machinery passages with periodic boundaries.

Related Topic: