Manual Convergence

The Solution Control dialog controls the solution progression rate so that the chance of divergence is minimized. Values are adjusted by moving the slider bar toward “Slower” or “Faster” between 0 and 0.5 (or in some cases, 1.0). Note that if you specify 0, the degree of freedom will not be allowed to progress with the solution at all.

The default values are the best settings for most analyses. However, if Intelligent Solution Control is disabled, solution difficulties can often be resolved by manually reducing the progression rate for pressure to 0.1-0.3. This is generally the most effective way to minimize solution difficulties, particularly if they occur in the early iterations of a calculation. Reducing the rate on the velocity components, in conjunction with pressure, to 0.1-0.3 may be necessary in some cases.

The progression rate on variables and properties can be adjusted only for those quantities that are changing in the analysis. For example, the temperature rate can only be adjusted if Heat Transfer is turned On on the Options dialog. Likewise, the progression rate on the Density, Specific heat (Cp), and Conductivity properties can only be adjusted if these properties are variable, as set in the Material Editor.

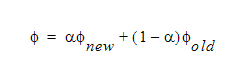

The progression rate is applied to the solution in the following manner:

where  is the current solution,

is the current solution,  is the previous value and

is the previous value and  is the relaxation value. This value should be in the range of 0.0 to 1.0. If a value of 0.0 is used, the new solution is ignored. If 1.0 is used, the previous value is ignored. For most situations, the value of 0.5 is best. If convergence difficulties occur, lowering the pressure relaxation to a value of 0.1-0.3 may solve the problem.

is the relaxation value. This value should be in the range of 0.0 to 1.0. If a value of 0.0 is used, the new solution is ignored. If 1.0 is used, the previous value is ignored. For most situations, the value of 0.5 is best. If convergence difficulties occur, lowering the pressure relaxation to a value of 0.1-0.3 may solve the problem.

Example applying manual convergence controls

For compressible analyses, an additional method of control is also available: Pressure Control and Temperature Control. (Temperature Control is available for incompressible analyses as well.) A value between 1e-3 and 1e-6 can be selected for these parameters. They are necessary for compressible analyses because the numerical conditioning for such analyses can often be poor. For most compressible analyses, a value of 1e-3 is adequate for pressure (and temperature if Heat Transfer is enabled in the Options dialog). However, if convergence difficulties persist, it may be necessary to reduce the value.

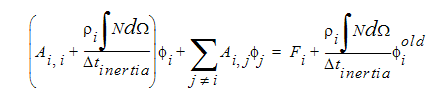

The value set for Pressure and Temperature control is a sort of pseudo-transient relaxation that is implemented in the solution in the following manner:

This form of relaxation is called inertial relaxation. Where under-relaxation is typically applied to the solution variables themselves, inertial relaxation is used in the governing equations to slow the solution down in the same manner as the transient terms for non-steady problems.

The second term within the parentheses and the last term on the right hand side of this equation are the inertial relaxation terms. The  can be adjusted to affect the influence of inertia.

can be adjusted to affect the influence of inertia.