The CFD Story

Video Notes:

Introduction

One of humanity's oldest challenges has been to understand and harness the power of the elements, the strength of wind, and the force of water.

This quest inspired some of history's greatest minds to develop the science of Fluid Dynamics, and its equations.

These equations are nothing short of genius, and very difficult to solve.

They are so complex, in fact, that humans simply cannot solve them by hand. This complexity has led to a software revolution that uses computers to predict the behavior of liquids and gases and how they work with the products we design.

We call this Computational Fluid Dynamics, or CFD for short.

Why should you use CFD?

Fluids affect the performance of just about every widget, device, and structure. CFD is an important part of the design process, and benefits areas such as energy efficiency, risk reduction, and innovation…

Energy Efficiency:

Fluids are all around us, and are always a serious factor. It takes energy to move a car down the highway or to pump water through a pipeline.

By understanding the forces and effects of fluid dynamics, you can make the critical design decisions that reduce energy consumption and improve efficiency.

Risk Reduction:

Products, vehicles, and structures often fail due to miscalculations or judgment errors about fluid behavior. We hear about these problems in the news...computers overheat; car parts fail; structures collapse in high winds. The result is recalls, lawsuits, or worse, loss of life.

By running CFD analyses throughout the design process, you can reduce risk by catching and solving many of these issues before they turn into serious problems.

Innovation through Insight:

Costly physical prototype testing provides discrete pieces of test data, and is expensive and time consuming. CFD analysis shows the complete view of the flow. This insight inspires questions and critical thinking that lead to innovative design.

What can you do with CFD Analysis?

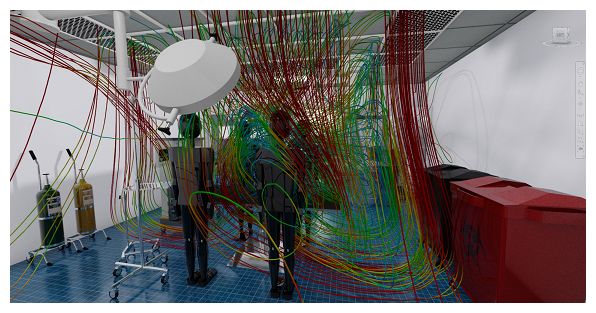

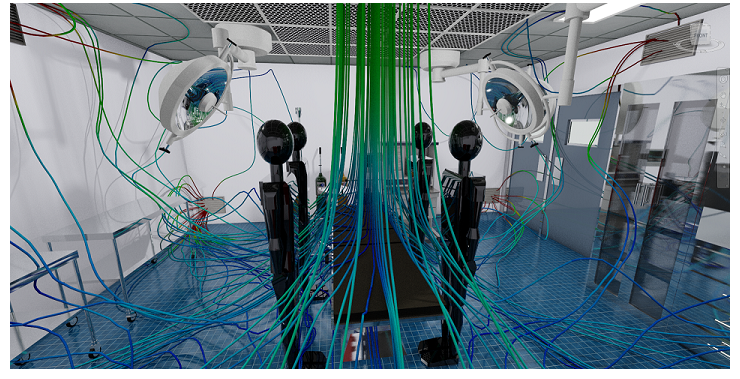

Fluid Flow is the study of how liquids and gases move in and around solid objects. Heat Transfer is the study of how things get hot or cold, and why.

With CFD analysis, you can understand the flow and heat transfer throughout your design process. Let's look at a few examples:

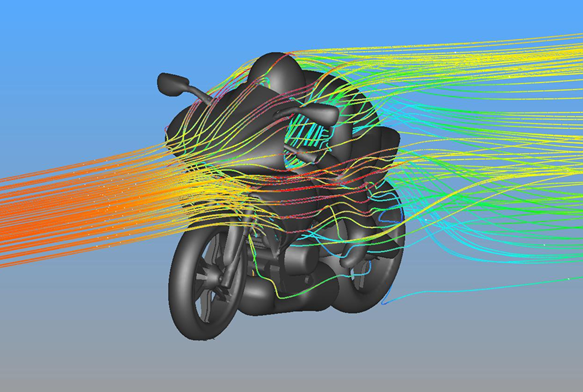

Wind resistance of a car or motorcycle:

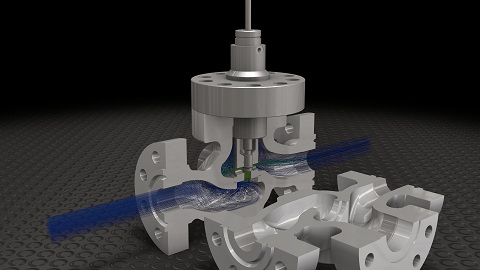

Pressure drop through a valve:

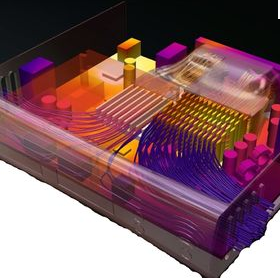

Component temperatures in an electronics enclosure:

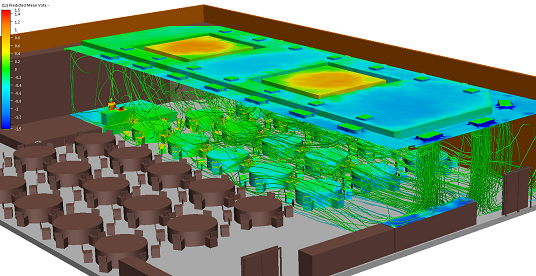

Comfort of people in a crowded meeting hall:

And that's just the start...

When should you use CFD Analysis?

You can use CFD analysis throughout the design process to gain insight and to make good design decisions. Let's look at an example...

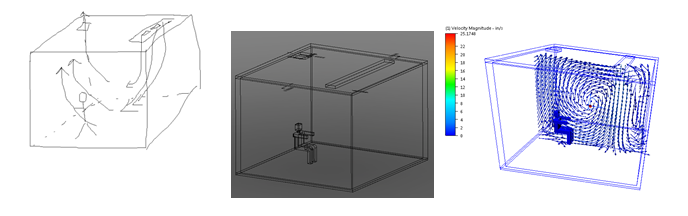

Concept:

Let's say you have an assignment, and right away you have an idea for solving the problem. You think it will work, so you mock it up, and run a CFD analysis. You learn some things; you get ideas. You land on a concept that will drive the next Big Thing…

Design Evolution:

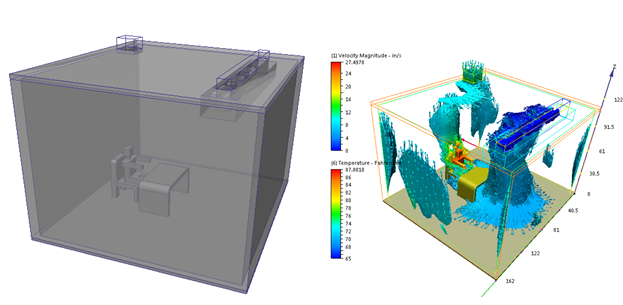

As you work out the details, you consider every question carefully.

You iterate through each alternative, and select the best. Each analysis unlocks a tiny secret that makes your design better.

Validation:

As a last step, you analyze a detailed model to check that it all works as designed. You spot an issue, fix it, and then rerun to check the fix.

The result is a high-quality product, delivered on-time. Your customers are happy, and you're ready for the next big challenge!

Next Steps

The next video is about the Simulation CFD Process.

Alternatively, you can return to the Quick Start home page to watch a different video, do a tutorial, or start applying what you've learned.