Subdiv Weld

Subdiv Weld

Merges subdivision edges or CVs. Using the Subdiv Weld tool you can:

- Merge a selected edge to a target edge.

- Merge edges or CVs at a midpoint.

- Merge all the selected edges that are within a specified distance from each other.

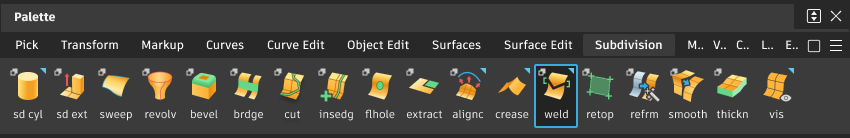

Access the tool from the Subdivision Palette:

Subdiv Weld settings

Weld Type

To Target - Welds by making the target edge the new edge and deletes the source edge.

To Midpoint - Welds by creating a new edge or CV at the equidistant between the source and target components. The source and target components are then removed.

To Tolerance - Welds using the To Midpoint weld type for selected edges that are within the specified Weld Tolerance distance.

Weld Tolerance:30

Weld Tolerance

Specifies the distance in the set scene units when welding using To Tolerance. Selected edges or CVs located within this set distance get welded.

Weld tool workflows

Subdivision edges to a target edge

Shift-select the tool to open the control window.

In the control window, set Weld Type to To Target.

Select the source edge and then the target edge.

The target edge is now the new edge and the source edge is deleted.

Subdivision edges at a mid point

Shift-select the tool to open the control window.

In the control window, set Weld Type to To Midpoint.

Select the source and target edges or CVs.

The components are merged by creating a new edge or CV at the midway point between the source and target components. The source and target components are removed.

Subdivision edges using a tolerance value

Shift-select the tool to open the control window.

In the control window do the following:

- Set Weld Type To Tolerance.

- Beside Weld Tolerance, specify the minimum distance within which selected edges or CVs get merged.

Select the source edge and target edges.

Selected edges that are within the specified Weld Tolerance are merged at the midpoint distance between them. A new edge or CV is created and the source and target components are removed.