Stitch and Seam Surface

Stitch and Seam Surface

Automates the creation of seams and stitching.

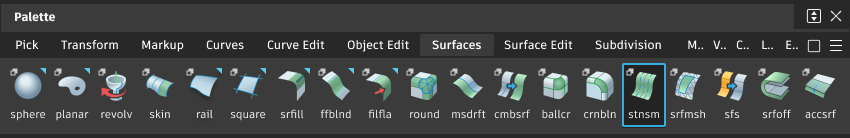

Access this tool from the Surfaces palette:

Stitch and Seam settings

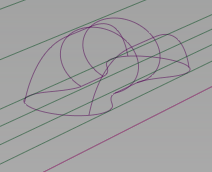

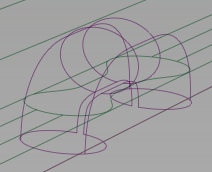

Seam

Seam Type

French

Deck (similar to a "flat fell" seam)

Join

Baseball

None (stitch with no seam)

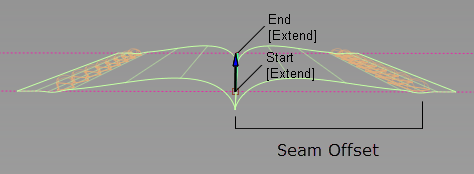

Seam Offset

The distance from the seam to the stitches.

For Join type seams (which do not have top-stitching), the stitch surfaces do not extend past this offset distance.

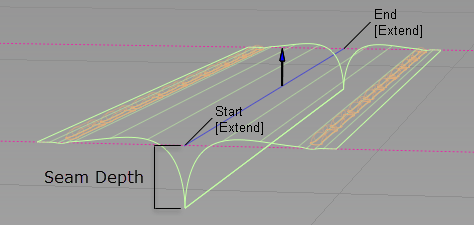

Seam Depth

The distance from the curve-on-surface to the seam.

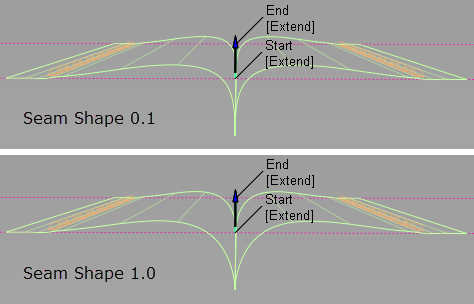

Seam Shape

The shape or curvature of the seam surface at the seam. Smaller values give a tighter seam, larger values a more open seam.

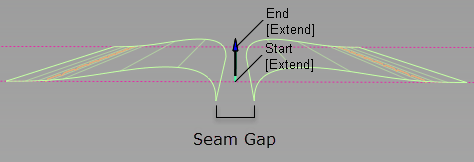

Seam Gap

The space between the surfaces at the seam.

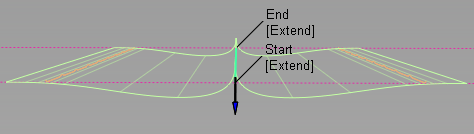

Flip Surface Side

Flips the direction of the seam surfaces and stitches.

Flip Seam Side

For the Deck seam type, flips the side of the surface the seam is created on.

Flow Control

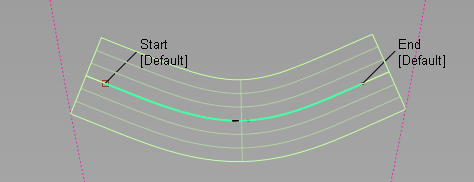

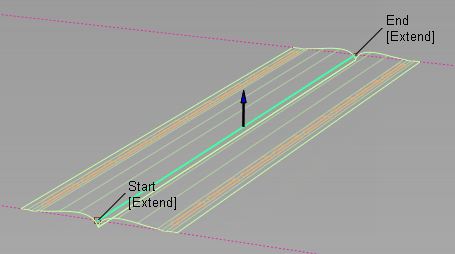

Start/End

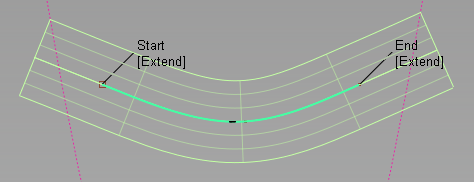

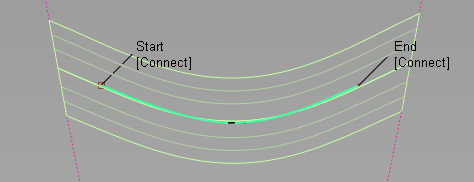

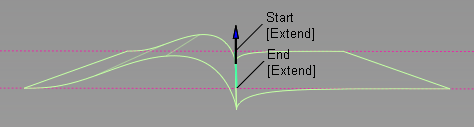

Controls how the edges of the seam surfaces meet the edges of the surfaces on which they are created.

Default – The end edges of the seam surfaces remain perpendicular to the curve-on-surface.

Extend – The seam surface end edges are extended so that they reach the surface edges while remaining perpendicular to the curve-on-surface.

Connect – The seam surface end edges meet the surface edges exactly.

Edge Align – The tool tries to align the seam surface end edges with the edges of the surface.

Modify Range

When this option is selected, Start and End sliders appear in the control window, and arrow manipulators appear on the selected curve-on-surface. Drag these arrows to modify the extent of the seam along the curve-on-surface.

Start/End

Use these sliders to modify the extent of seam along the curve-on-surface. Start and End values of 0.0 and 1.0 respectively, define the original extent.

Bulge

Create Bulge

Create a swelling or bump on one or both sides of the seam. If only one side is selected, the Bulge Size is applied to that side, and a Bulge Size of 0.0100 is applied to the other.

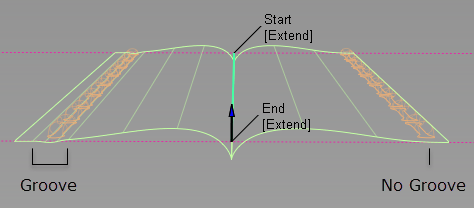

Groove

Create Groove

For French seams only. Create an indent along the stitching line of one or both sides of the seam. Increase the Groove Size for a wider indent along the stitch line.

Decreasing the Groove Size may decrease the Stitch Diameter and could also result in a seam that appears to have no stitches. Increasing the Groove Size does not automatically increase the Stitch Diameter.

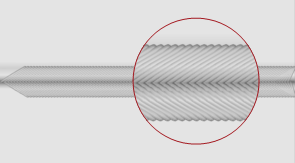

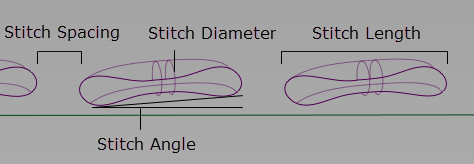

Stitches

Create Stitch

For French and Baseball seams only. Create stitches on one or both sides of the seam.

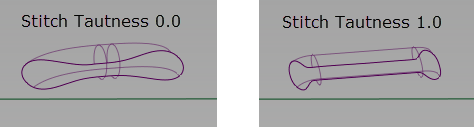

Stitch Tautness

Changes the shape of the geometry to represent stitches that are pulled tight. As tautness increases, the stitch profile becomes flatter and more elliptical.

Quick Stitch

Creates stitches with fewer spans to increase update speed.

Trim

Stitches – Trims the stich surfaces where they intersect the seam surfaces. Deselect this option to increase the update speed.

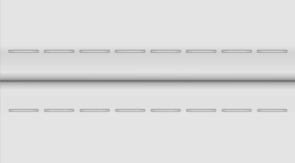

Trim: Stitches

Seams – Trims the seam surface where it intersects the stitch surfaces.

Trim: Seams

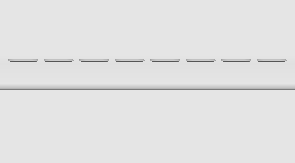

Add Jitter

Adds slight variations to the stitch angles for a more realistic look.

Add Jitter not selected

Add Jitter selected, Stich Jitter value of 1

Stitch Jitter

Sets how much variation in the stitch angles.

Stitch and Seam common parameters

Stitch and Seam has the following Surface Tool Common Parameters sections:

- Flow Control

- Control Options

Stitch and Seam workflow

Create a seam and stitch geometry

Automate the creation of seams and stitching for visualization. Using a curve-on-surface to define the seam line, use the Stitch and Seam tool to create seam and stitch geometry.

Create a seam and stitch geometry

Select the tool.

Select the curves-on-surface that define the seam and do one of the following:

- If the selected curve-on-surface geometry is sufficient to create the seam, click Accept.

- If the curve-on-surface is near the edge of its surface, then you may need to add neighboring surfaces to the primary selections. This ensures that the tool has enough geometry to properly generate the seam. To do this, click Add Primary, select the surfaces, and then click Accept.

Set options in the Stitch and Seam Control window and click Build.

Select the stich geometry in the Outliner and change their shader so you can differentiate them from the surfaces.