Symmetric Fillet

Symmetric Fillet

Creates a blend defined by one edge (tangent line) on a surface set. A tangent or curvature fillet surface(s) is built to match to a second surface set, and optionally the input surfaces are trimmed.

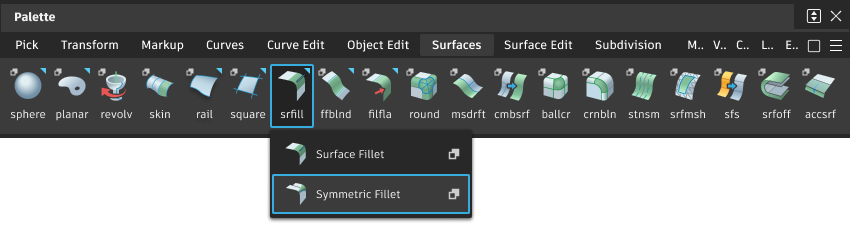

Access this tool from the Surfaces tool palette:

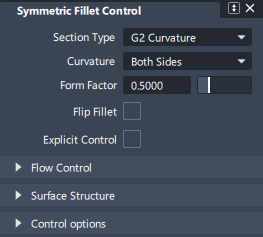

Symmetric Fillet settings

Section Type

This menu controls the shape of the fillet’s cross-section.

G1 Circular – Creates a fillet with circular cross-section, tangent to both sets of surfaces. This type maintains tangent continuity with the surfaces on either side.

G2 Curvature – Maintains curvature continuity (G2) with both sets of surfaces. G2 continuity means that the curvature (which is the inverse of the radius of curvature) is the same on both sides across the fillet’s boundaries.

G3 Curvature – Maintains G3 continuity with both sets of surfaces. G3 continuity means that the curvature’s rate of change is the same on both sides across the fillet’s boundaries.

When calculating the fillet, the V degree is adjusted so that the surface has enough CVs to provide the required continuity on both sides. Degree 5 is needed for G2 Curvature and degree 7 is needed for G3 Curvature.

Curvature

This option is only available when Section Type is set to G2 Curvature or G3 Curvature.

Side 1, Side 2 – Make the fillet surface curvature continuous with the first or second set of surfaces, and tangent to the other side.

Both – (Default) Make the fillet surface curvature continuous with both sets of surfaces.

Form Factor

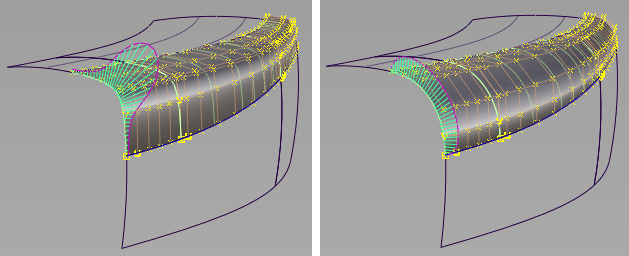

This parameter lets you adjust the shape of the fillet. It specifies the ratio between the lengths of the innermost and outermost CV arms of the hull in the V direction of the fillet. Values range from 0.1 to 2.0. The smaller the value, the sharper the bend in the fillet.

A G2 symmetric fillet with, left: form factor = 0.1, and right: form factor = 2.0.

Flip Fillet

This option corresponds to the blue arrow indicating on which side of the surfaces the fillet will be built. Checking or unchecking the box flips the direction of the arrow in the same way as clicking the arrow on the model.

Symmetric Fillet common parameters

Symmetric Fillet has the following Surface Tool Common Parameters sections:

- Explicit Control

- Flow Control

- Surface Structure

- Control Options

Symmetric Fillet workflows

In the Surfaces tool palette, select the Multi-Surface Fillet > Symmetric Fillet tool ![]() and follow the prompts:

and follow the prompts:

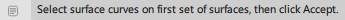

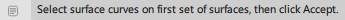

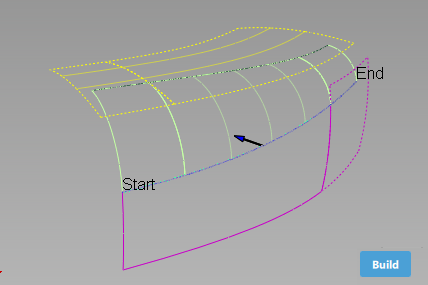

Select the surface curves to be used as tangent lines for the fillet. They can be surface edges, trimmed edges, curves-on-surface or isoparms, but they must be tangent continuous (G1).

Start and End labels appear, indicating the extent of the selected curves.

Click the Accept button.

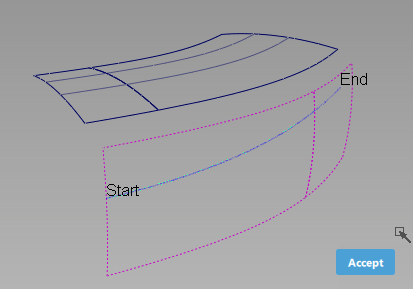

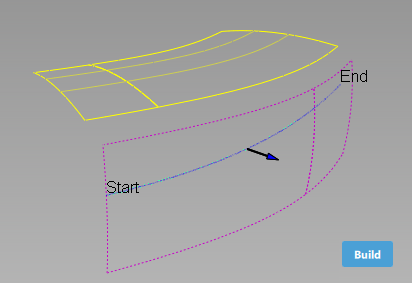

Select the second set of surfaces.

The surfaces are drawn in yellow.

Click the Accept button.

A blue arrow appears, showing on which side the fillet will be built. Click on the arrow to flip it if needed, then click the Build button.

The symmetric fillet is built between the selected tangent line(s) and the second set of surfaces. By default the fillet is circular and extends the full length of the tangent line(s).

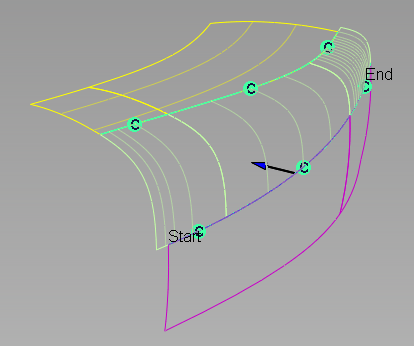

Open the control window and modify the parameters, then click the Update button to update the fillet.

In the example below, Section Type is set to G2 Curvature, Continuity Check is on, and both ends of the fillets have been extended, so that the surfaces can be trimmed (Trim Type is set to Automatic).

The symmetric fillet has construction history and will update whenever the input geometry is modified.