Use this procedure to model a parametric junction box MvPart. You add the rectangular geometry, create the profiles, apply the modifiers to create the box itself, and add geometry for the knockouts.

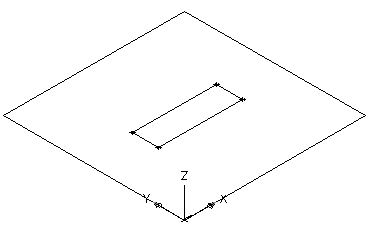

- In the part browser, right-click XY Plane and click Add Profile

Rectangular.

Rectangular. For more information about profiles, see Profiles.

- In the modeling area, specify the first corner and then the second corner.

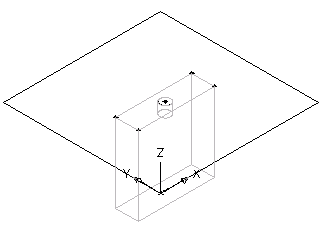

A rectangular profile for the top face is created and is added to XY Plane in the part browser. Constraints for the rectangular profile are added to XY Plane.

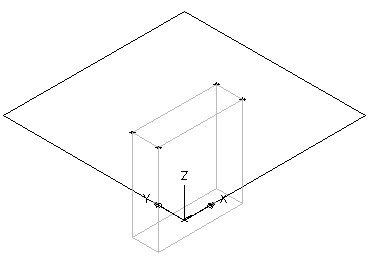

- In the part browser, right-click Modifiers and click Add Extrusion.

For more information about modifiers, see Modifiers.

- In the modeling area, select the rectangular profile.

The Extrusion Modifier dialog box is displayed.

- Under Termination, select Blind for Type, enter 15" (381 mm) for Distance, and click Flip. Click OK.

A box is created to represent the junction box and an extrusion modifier is added to Modifiers in the part browser.

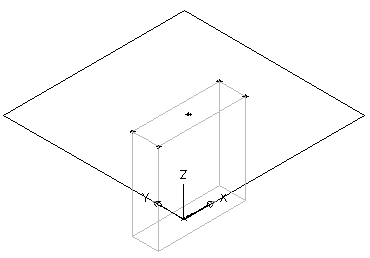

- To add the knockout, in the part browser, right-click XY Plane and click Add Geometry

Point.

Point. - In the modeling area, specify a point near the center of the top of the junction box, and press Enter.

- To constrain the point to the exact center of the top of the junction box, in the part browser, right-click XY Plane and click Add Constraints

Equal Distance.

Equal Distance. - In the modeling area, specify the pairs of geometric constraints.

For the first pair, select the point in the top center of the junction box, and then the lower-left edge of the rectangular profile.

For the second pair, select the point in the top center of the junction box, and then the upper-right edge of the rectangular profile.

Note: When adding constraints, you may be prompted that the geometry is unconstrained by a specific number of dimensions. These prompts are for informational purposes only to assist you during the modeling process. It is recommended that you add a minimum number of constraints to define the shape of the part to avoid undesirable results. - Repeat steps 8 and 9 to constrain the center point to the upper-left and lower-right edges of the top face.

The model of the junction box is updated to the specified constraints.

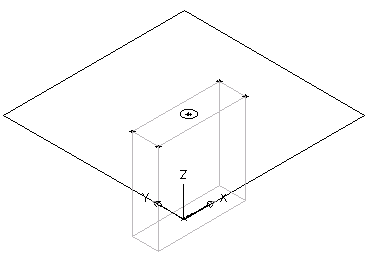

- In the part browser, right-click XY Plane and click Add Profile

Circular. Tip: You may find it easier to add the knockout in the top view, rather than in a model view direction. To change the view, click

Circular. Tip: You may find it easier to add the knockout in the top view, rather than in a model view direction. To change the view, click

Views drop-down

Views drop-down .

.

- In the modeling area, using object snaps, select the point in the top center of the junction box as the center of the circle, enter .5" (13 mm) for the radius, and press Enter.

A circular profile is created and is added to XY Plane in the part browser.

- To constrain the circular profile to the center of the top face, in the part browser, right-click XY Plane and click Add Constraints

Concentric.

Concentric. - In the modeling area, select the circular profile for the first geometry and the center point of the top face for the second geometry.

- In the part browser, right-click Modifiers and click Add Extrusion.

- In the modeling area, select the circular profile.

The Extrusion Modifier dialog box is displayed.

- Under Termination, select Blind for Type, enter 2" (51 mm) for Distance, and select Flip. Click OK.

A cylinder is created to represent the knockout and an extrusion modifier is added to Modifiers in the part browser.