You can specify a demand factor to calculate the estimated demand load from a circuit. The demand factor can:

- Be a constant value

- Be a constant value for all motors, except the largest motor

- Vary depending on the load total

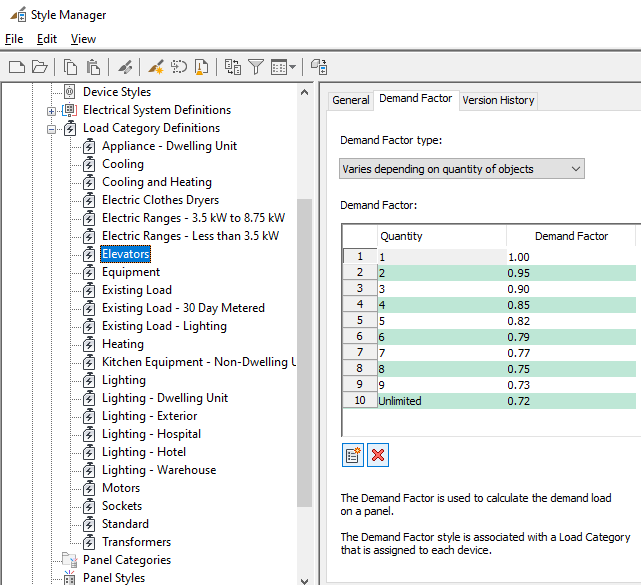

- Vary depending on the quantity of the objects

Each demand factor is assigned a value that is multiplied by the load to determine the demand for a load category. It is important to define a demand load so that you do not overload the circuit. Defining a demand factor also provides you with a real calculation of the estimated demand load.

For example, for the load category Lighting, with a demand factor of 1.00, if you have 10 lights at 60 VA each, the load is 60 VA x 10 (lights) = 600 VA. Therefore, the lights for the load of this load category would be 600 VA. However, this value applies only if all the lights are turned on at the same time. If you plan to have just half the lights on at a time, you would specify the demand factor as a constant value set to 0.5 (or 50%). The estimated load is then 600 VA x 0.5 (demand factor unit) = 300 VA. Building codes provide guidance what values to use for demand loads. For example, if the total receptacle load on a panel is 20,000 VA, the demand factor could be 15,000 VA depending on the local code.

Using a different example, if the demand factor were set to vary depending on the quantity of the objects, for example for elevators, the minimum demand factor value would be 72% (or .72). The estimated load is then 600 VA x 0.72 (demand factor unit) = 432 VA.

Demand factors are assigned to load categories and load categories are assigned to device connectors. The estimated load for a device is calculated by using the load and the value for the demand factor. The estimated demand load is displayed in the Circuit Manager and in the Panel Schedule. The Panel Schedule also shows the load for each load category style.

To create a load category definition

- Click

.

.

- Click Load Category Definitions. Right-click, and click New.

- Enter a name, and press Enter.

- Select the new load category style.

- On the General tab, enter a description for the load category.

- On the Demand Factor tab, select the demand factor type.

- Specify the value(s) for demand factor as necessary.